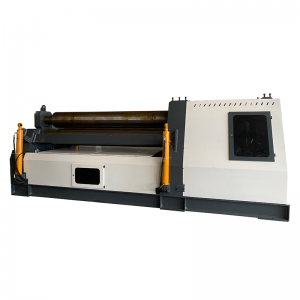

W12 -12 X2500mm CNC four roller hydraulic rolling machine

Working Principle

The hydraulic four-roll plate bending machine operates based on the principle of hydraulic transmission and metal plastic deformation. When the metal plate is fed into the space between the four rolls, the hydraulic system exerts pressure on the rolls. The upper and lower rolls apply pressure to the plate, causing it to bend plastically. By precisely controlling the movement of the side rolls through the hydraulic system, the curvature and shape of the plate can be accurately adjusted to achieve the desired bending effect.

Product introduction

The machine adopts the four-roller structure with the upper roller as the main drive,Both upward and downward movement Through hydraulic motors powered.The lower roller makes vertial movements and imposes a force on the piston through the hydraulic oil in the hydraulic cylinder so as to clamp the plate tight.Side rollers are arranged on the two sides of the lides of the lower roller,and make inclining movement along the guide rail,and provide drive through the screw,the nut,the worm and the lead screw.The advantage of the machine is that the preliminary bending and rolling of the top ends of the plates can be conducted on the same machine.

Product feature

1.High Bending Precision: It can achieve high-precision bending of metal plates, with an accuracy that can meet the strict requirements of various industrial fields. Strong Power: The hydraulic system provides strong power, enabling it to bend thick and large plates with ease.

2.Good Stability: The hydraulic drive system ensures stable operation of the equipment, reducing vibration and noise during the bending process and improving the quality of the processed products.

3.Easy to Operate: It is equipped with an advanced control system that allows operators to easily adjust parameters such as bending radius and pressure, facilitating efficient operation.

Product application

Hydraulic four - roll plate bending machines are widely applied across multiple industries.

1.Shipbuilding

They are crucial for bending hull plates into complex shapes, ensuring a proper fit for the ship's hull structure and hydrodynamic performance. Also, they're used to form components like bulkheads and decks.

2.Pressure Vessel Manufacturing

These machines play a key role in creating cylindrical and conical parts for boilers, reactors, etc. High - precision bending ensures the pressure vessels meet strict safety and quality standards.

3.Aerospace

In aircraft manufacturing, they're used to process the aircraft skin, achieving the required smooth curvature for better aerodynamics. They also contribute to manufacturing structural components like wing ribs.

4.Bridge Construction

For fabricating steel box girders in bridges, hydraulic four - roll plate bending machines bend steel plates accurately, guaranteeing the stability and mechanical properties of the bridge structure.

5.Mechanical Equipment Manufacturing

They assist in manufacturing parts such as rolling mill rollers and the shells of large motors, enhancing the quality and efficiency of production.

Product parameter

| Material/Metal processed:Aluminum,carbon steel,sheet metal,rion plate,stainless steel |

Max working length(mm):2500 |

| Max plate thickness(mm):12 | Condition:new |

| Place of origin: jiangsu,china | Brand name:Macro |

| Automatic: automatic | Warranty: 1 year |

| Certification: CE and ISO | Product name:4 roller rolling machine |

| Machine type: roller-bending machine | Max rolling thickness(mm): 12 |

| After sale service:online support,video technical support,field maintenance and repair service |

Voltage:220V/380V/400V/600V |

| Plate yield limit:245Mpa | Controller: siemens controller |

Samples