Products

-

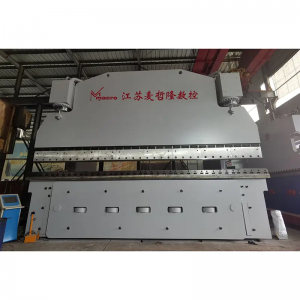

Estun E21 controller WC67Y-100T/2500mm hydraulic press brake bending machine

Depending on the material, maximum bending thickness and length, the right type of hydraulic press brake can be selected. Hydraulic press brake machines can bend sheets of different thicknesses with high precision. The body is overall-welded with steel plate as a whole, the structure is stable, the strength of the bending machine is high, and the internal stress is eliminated.It is widely used in sheet metal processing industry.

-

Hot sale WC67Y-125T/3200mm hydraulic press brake bending machine

Hydraulic press brake machines can efficiently bend various high-precision metal sheets. When bending sheets of different thicknesses, shapes or sizes, upper dies with different shapes or V-groove lower dies with different opening sizes should be selected. Select the size of the tonnage of the bending machine, which can be obtained from the bending force calculation formula, or can be found from the bending pressure gauge. The bending machine works smoothly and is easy to operate. The whole machine adopts a steel plate welded structure and is treated with overall vibration to ensure the precision and strength of the hydraulic press brake machine.

-

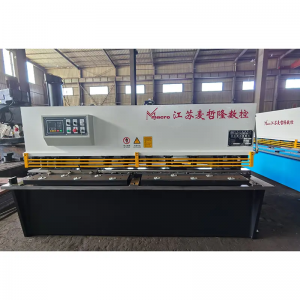

High precision QC12Y-10X5000mm hydrauclic sheet metal shearing machine

The whole hydraulic shearing machine adopts vibration to eliminate stress, and the whole machine is welded, which is durable and stable in structure. The metal plates of different thicknesses are cut by adjusting the blade gap, and the shearing force is applied to the metal plates of various thicknesses through the moving upper blade and the fixed lower blade, so that the plates are separated.It can meet the shearing needs of different thicknesses.It is equipped with safety guardrails to ensure the safety of workers operating the hydraulic shearing machine.

-

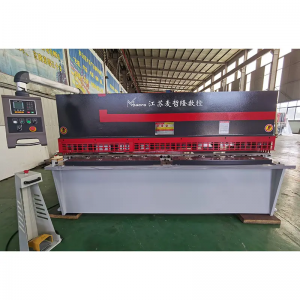

High precision QC12Y-6X3200mm hydrauclic sheet metal shearing machine

The hydraulic shearing machine adopts an integrated hydraulic control system, which is easy to operate,runs smoothly, the shearing angle is adjustable, and the blade gap is adjustable, so that the shearing deformation of the sheet metal can be effectively prevented, and the parallelism of the cutting can be ensured,cutting metal plates with high precision.Equipped with high-precision back gauge, has high accuracy position,high quality ball screw and linear guide can be optional, to ensure working with high efficiency.

-

High precision QC12Y-4X3200mm hydrauclic sheet metal shearing machine

QC12Y-4X3200mm hydraulic swing beam shearing machine can cut maximum 4mm thickness ,3200mm length of sheet metal plate smoothly,shearing plate without burr.It adopts welded steel plate structure, hydraulic drive, and the hydraulic shearing machine has good rigidity and strength. Adopt advanced integrated hydraulic system with high reliability. The shear angle is variable and has good cutting performance. The pendulum hydraulic shearing machine cuts thin and thick plates, and the gap between the knife edges can be adjusted to ensure cutting accuracy and quality. According to the length of the shearing plate, the back gauge can be precisely positioned, and the position can be adjusted by the motor, so as to cut high-quality workpieces.

-

High precision QC12Y-8X4000mm hydrauclic sheet metal shearing machine

QC12Y-8X4000mm Hydraulic swing beam shearing machine can cut 8mm,4000mm sheet metal plates smoothly.The hydraulic pendulum shearing machine adopts an all-steel welded structure to ensure the overall high precision of the fuselage. Hydraulic pendulum structure, upper tool rest return device, nitrogen cylinder type, the machine return speed is fast. The hydraulic system has simple structure, stable action, low noise and convenient operation. The German Rexroth hydraulic valve is used to control the smooth operation of the blade, and the blade clearance can be adjusted to meet the shearing needs of different plate thicknesses and materials.

-

High precision QC11Y-20X4000mm hydraulic guillotine shearing machine

Best quality QC11Y-20X4000mm hydraulic guillotine shearing machine can cut 20mm thickness, 4000mm length of carbon steel plates with high efficiency.The whole machine of the hydraulic guillotine shearing machine adopts integral welding, and the welding parts such as wall panels, worktables, and tool rests vibrate to eliminate stress, and the stability of the machine tool is high. The use of tandem oil cylinders has good synchronization performance, so that the hydraulic guillotine shearing machine has high precision when shearing sheets.Accumulator return travel can be smooth and fast, it can cut plates with high efficiency.

-

High precision QC11Y-16X4000mm hydraulic guillotine shearing machine

The hydraulic guillotine shearing machine is welded with high-quality steel plates, which eliminates stress by vibration and has high frame stability.Macro factory QC11Y-16X4000mm hydraulic guillotine shearing machine can cut maximum 16mm thickness, 4000mm length of sheet metal plates with high efficiency.Through the nitrogen return, the speed is fast and the impact force is small.Photoelectric protection device is optional.The hydraulic guillotine shearing machine can adjust the shearing stroke, realize the function of segmented shearing, and greatly improve the shearing efficiency.

-

WE67K-2X1200T/8000mm CNC ESA S630 controller tandem hydraulic press brake bending machine

WE67K-2X1200T/8000mm CNC tandem press brake machine is composed of 2 sets of 1200T/8000mm CNC hydraulic bending machine, it can bend 16 meter length of Light pole、 Elevator、 Logistics equipment ,etc. It is equipped with ESA S630 CNC fully automatic controller system,with high degree of automation.The double-machine linkage bending machine can realize synchronous work. Each bending machine is composed of a worktable, a sliding block and left and right wall panels. The frame has sufficient rigidity. Under the action, the sliding block is driven downward. The slider is equipped with an upper die, and when the upper and lower dies contact the workpiece, the workpiece is bent and formed.

-

High precision WC67Y-200T/3200mm hydraulic press brake machine

Macro factory high quality of hydraulic bending machine adopts an all-steel welded structure with high strength, and the wall panel adopts a C-shaped structure, which can process extra long and large workpieces with high efficiency.WC67Y-200T/3200mm hydraulic press brake machine can bend 8mm thickness,3200mm length of metal sheet plate, or bend 4mm thickness, 3200mm length of stainless steel plate with high accuracy.Hydraulic press brake machine left and right are with safetyguard, backside safetyguard can be optional, to guarantee operating safety. All hydraulic press brake machines are equipped with germany EMB tube and connector, widely use, easy installation, high reliable sealing performance.

-

High precision WC67Y-80T/2500mm hydraulic press brake bending machine

Hydraulic bending machine is mainly composed of frame, stroke adjustment, front support, back gauge, mold, electrical system, hydraulic system and other parts. The hydraulic press brake machine has a simple structure and good rigidity. It is equipped with upper and lower molds of different shapes, which can bend workpieces of various shapes with high efficiency and high precision, and has high production efficiency. The oil cylinders on both sides of hydraulic press brake machine directly drive the sliding block to work, and it adopts electrical-hydraulic control, which can perform single, continuous, jog and halfway stop operations, and it is easy to realize automatic operation.

-

CNC Delem DA66T 6+1 axis WE67K-300T/4000mm hydraulic press brake machine

The frame of the full CNC electro-hydraulic servo bending machine adopts a new rigid design, and the frame adopts a steel plate integral welded structure to eliminate internal stress and ensure the overall high precision of the machine tool, so that the bent workpiece has a high straightness. Equipped with German Rexroth electro-hydraulic proportional servo synchronous control system, the synchronizing error of the slider can be detected through the grating ruler, thus ensuring the high synchronization accuracy of the slider. The CNC hydraulic press brake machine is equipped with a slow return function, and the operator can better control the bending speed of the workpiece to ensure that each workpiece is bent with high precision.