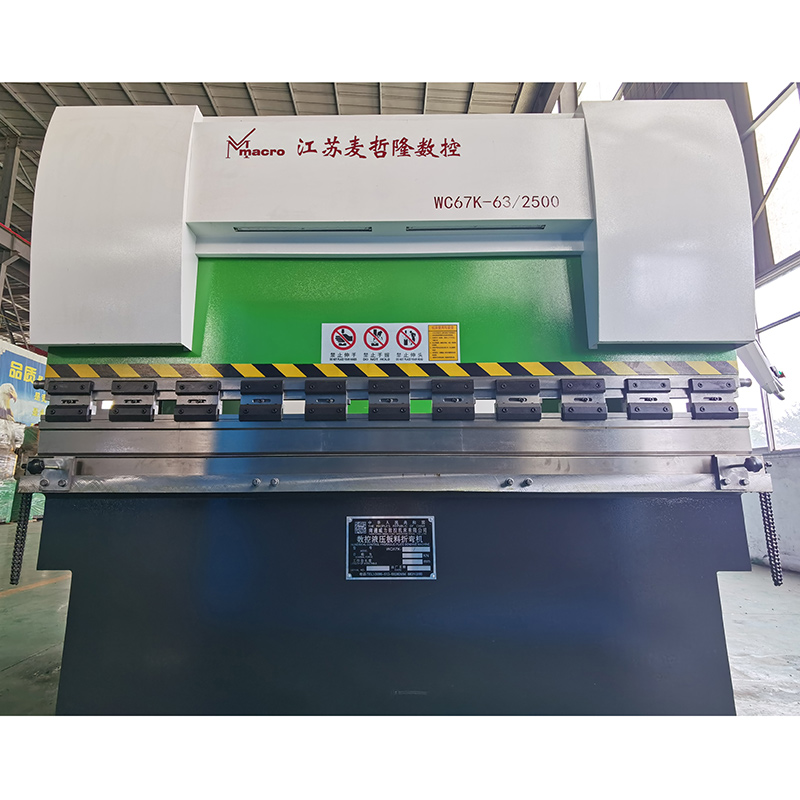

PriceList for 22 Cnc Hydraulic Press Brake - High accuracy WC67Y-160T/4000mm hydraulic press brake bending machine – Macro

PriceList for 22 Cnc Hydraulic Press Brake - High accuracy WC67Y-160T/4000mm hydraulic press brake bending machine – Macro Detail:

The hydraulic press brake machine is mainly composed of the fuselage part, the electrical control part and the hydraulic part. The hydraulic upper transmission is adopted, and the oil cylinders installed at both ends of the machine tool are connected with the slider, which can directly drive the slider to work, and the work efficiency is high. Equipped with high-quality molds, the mold has a long service life, and the upper mold can be equipped with a quick clamping device, which can quickly replace the mold, thereby improving production efficiency. The upper die has a manual fine-tuning device, which improves the precision of the bending workpiece and the service life of the die.Hydraulic press brake machine double oil cylinder synchronization, can greatly improve the bending accuracy.

Feature

1.The whole steel of hydraulic press brake machine is good and the stability is high.

2.Hydraulic press brake machine bending frequency response hydraulic control technology, more stable machine tools, more reliable operation.

3.X axis and Y axis realize accurate positioning function by frequency converter through NC E21 system programming control.

4.Schneider electric components reliable safety, long life, good anti-interference ability

5.Adopt high-precision ball screw and linear guide-way.

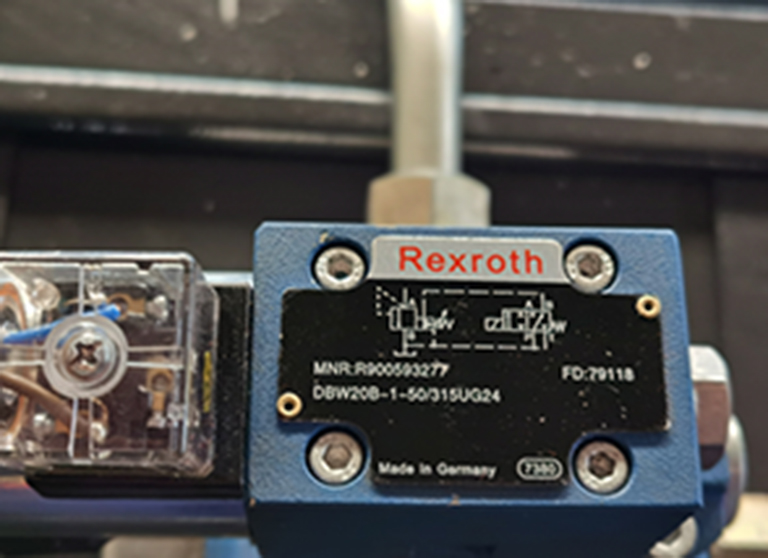

6.Adopt imported rexroth valve,protect hydraulic system

7.With best configuration of simens motor to provide power

8.Satisfy CE/ISO high standard

Application

Hydraulic press bake bending macine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):4000mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):1600KN |

| Motor Power(kw):11KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:320mm | CNC or CN: CNC controller system |

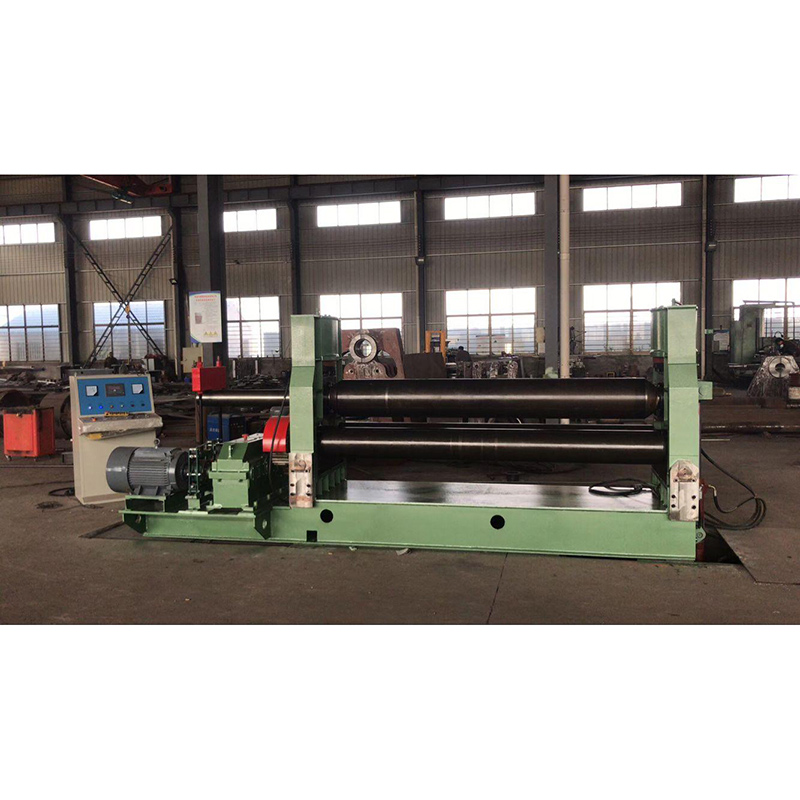

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Samples

Machine Details

Estun E21 controller system

Program memory of up to 4 programs

Up to 25 steps per program

One side positioning

one-key backup and restore function of parameters

Programs can be restored any time when need

Easy operating

Overall welding

Overall welding is high rigidity,high stability

Moulds

High precision moulds ensure the die service life

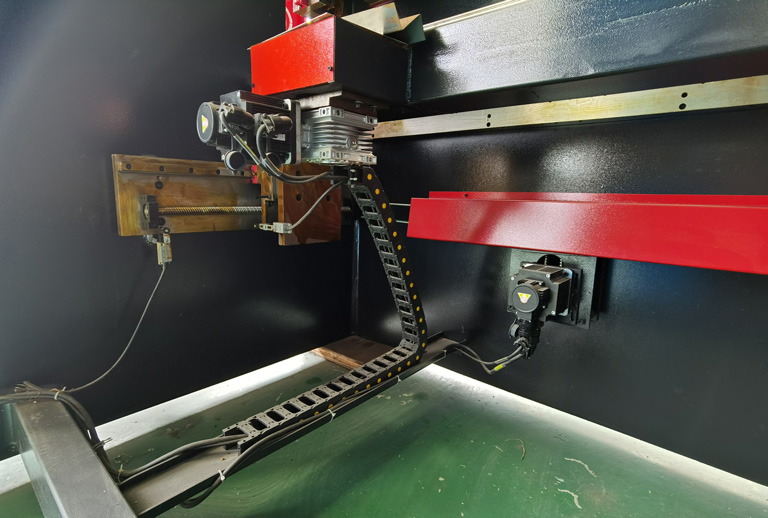

Ball screw and linear guide

has high precision,and low noise,have good perfomance

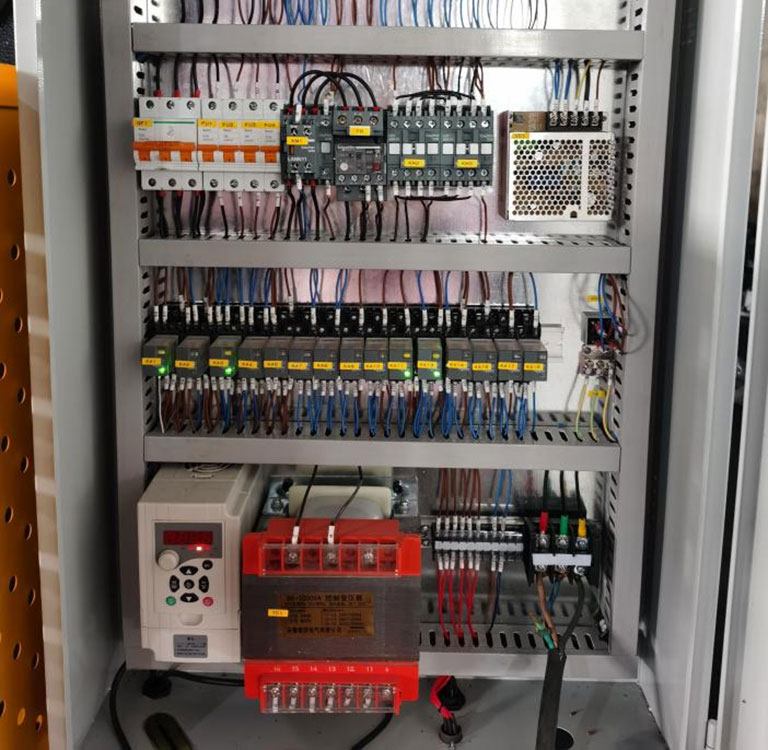

France Schneider electrics and DELTA inverter

Electrics system is france schneider , with DELTA inverter,has high quality

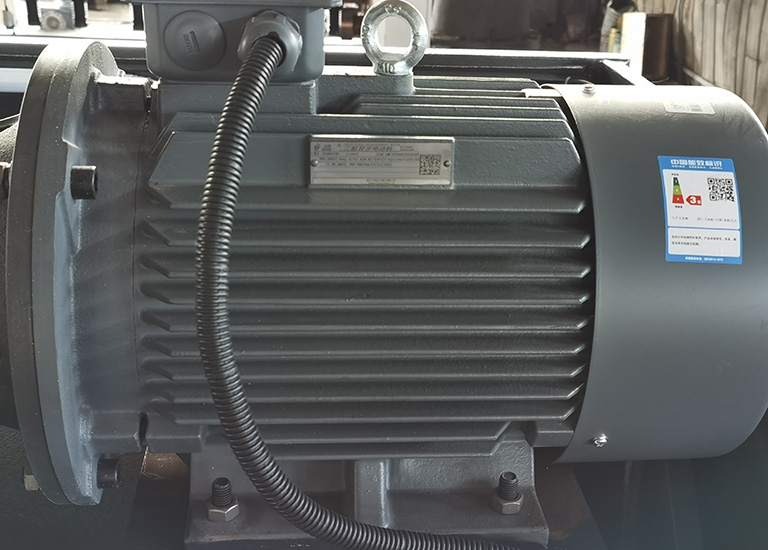

Siemens motor

Using germany siemens motor guarantee the machine service life,reduce noise,working stability

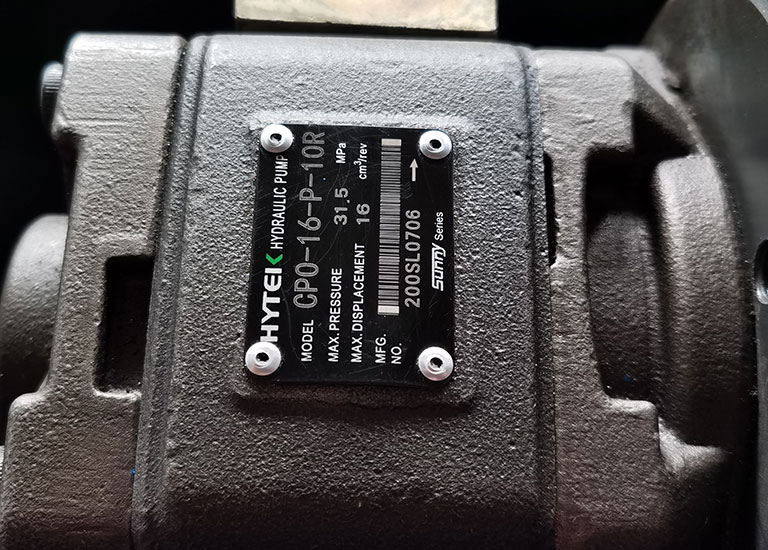

Sunny oil pump

Using Sunny oil pump,has long life,high efficiency,low noise

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Quick clampings

Using high quality fast clampings ,higher safety when changing moulds

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Optional Controller System

Product detail pictures:

Related Product Guide:

Our personnel are always in the spirit of "continuous improvement and excellence", and with the superior quality products, favorable price and good after-sales services, we try to win every customer's trust for PriceList for 22 Cnc Hydraulic Press Brake - High accuracy WC67Y-160T/4000mm hydraulic press brake bending machine – Macro , The product will supply to all over the world, such as: Mongolia, Nepal, Miami, Looking forward, we will keep pace with the times, continuing to create new products. With our strong research team, advanced production facilities, scientific management and top services, we will supply high quality products to our customers worldwide. We sincerely invite you to be our business partners for mutual benefits.

Perfect services, quality products and competitive prices, we have work many times, every time is delighted, wish continue to maintain!