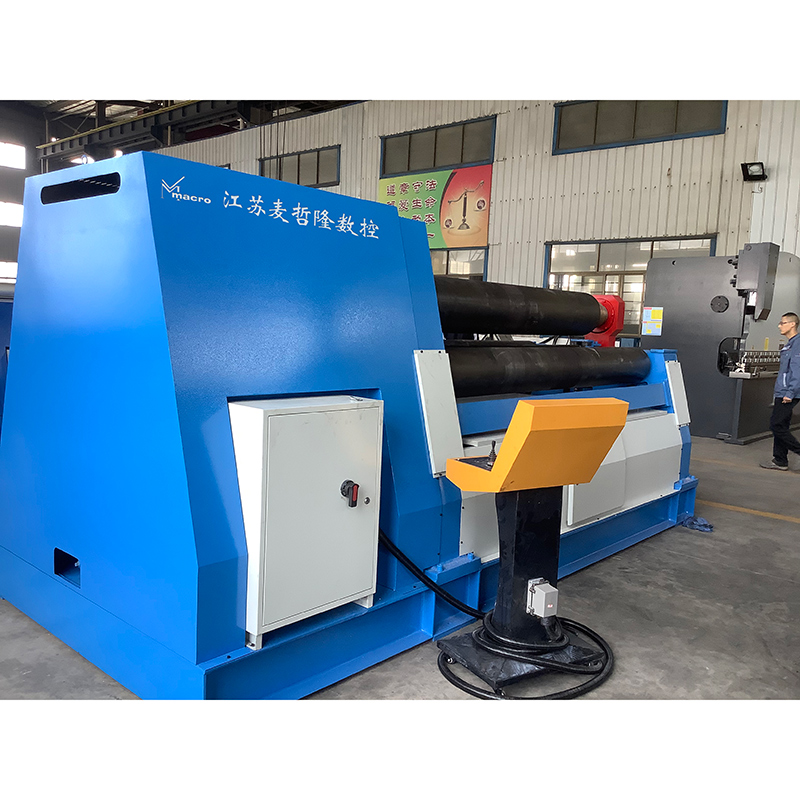

OEM manufacturer 60 Ton Press Brake - Hot sale WC67Y-125T/3200mm hydraulic press brake bending machine – Macro

OEM manufacturer 60 Ton Press Brake - Hot sale WC67Y-125T/3200mm hydraulic press brake bending machine – Macro Detail:

The hydraulic press brake machine is mainly composed of a frame part, a slider part, a synchronizing mechanism, a front support device, a back gauge, a mold and other parts. The hydraulic upper transmission is stable and reliable, the torsion shaft is synchronized, and the precision is high. Hydraulic press brake machine adopts steel plate welded structure, vibration eliminates internal stress, good rigidity and long machine life. It is equipped with Estun E21 controller system,can easy operate. It adopts germany siemens motor, can ensure whole hydraulic press brake machine working stability. Through different kinds of moulds, different shapes of workpiece can be bend with high accuracy.

Feature

1.Full EU streamlined design, heat treatment rack,high rigidity worktable.

2.NC Estun E21 controller system has working-piece counting function.

3.The rear baffle and the upper slider are equipped with encoders,high precision

4.Backgauge runs smoothly,with high precision

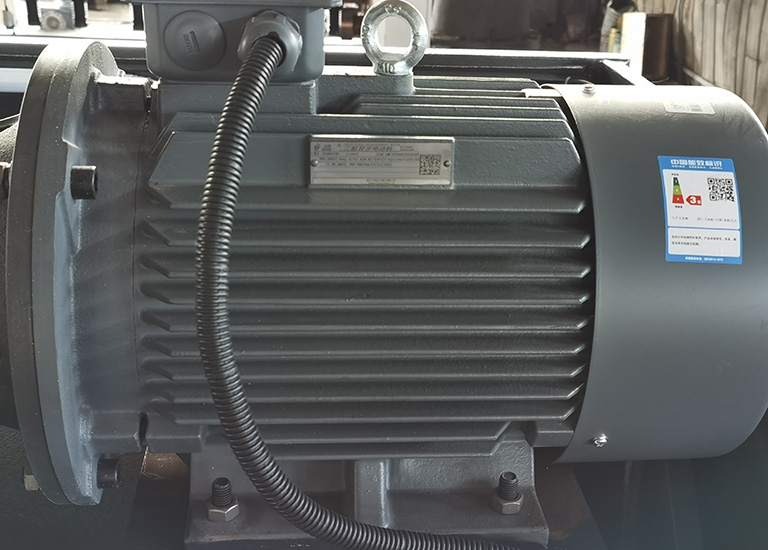

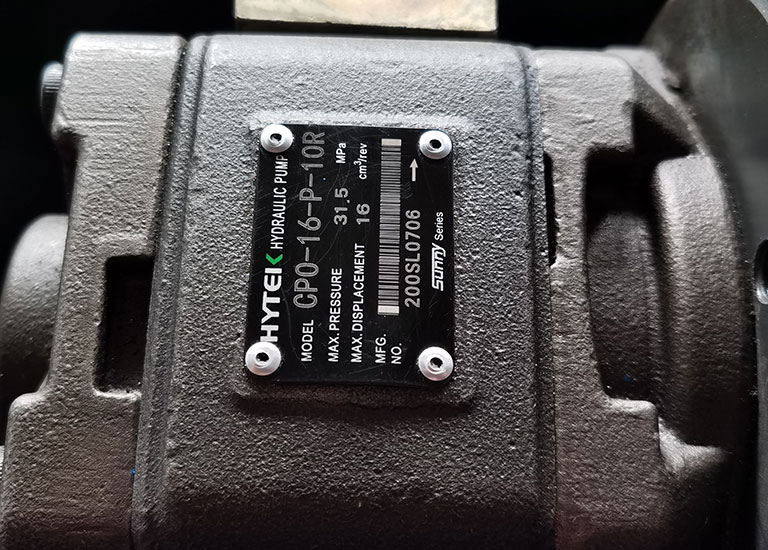

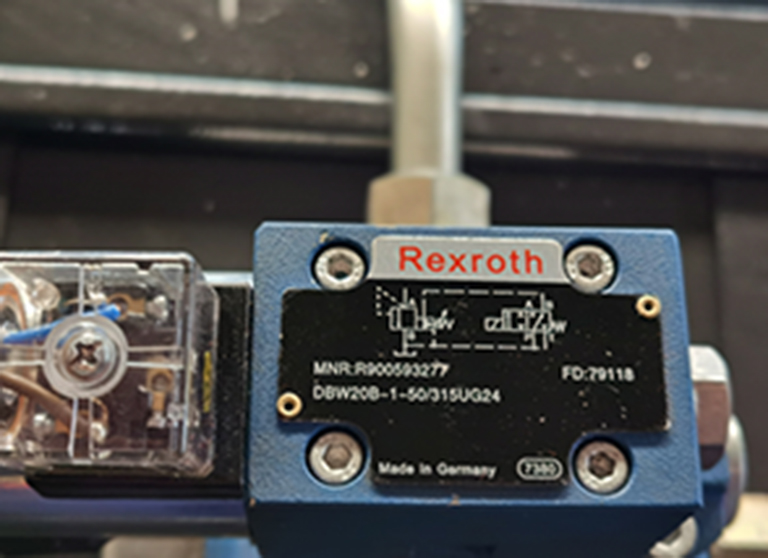

5.Imported germany siemens motor,rexroth valve,sunny pump

6.Imported germany EMB Oil Tube Connectors,ensure machine has long life

7.Optional photoelectric protection,easy operating

8.Conform to CE and ISO9001 standard

Application

Hydraulic press bake bending macine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):3200mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):1250KN |

| Motor Power(kw):7.5KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:320mm | CNC or CN: CNC controller system |

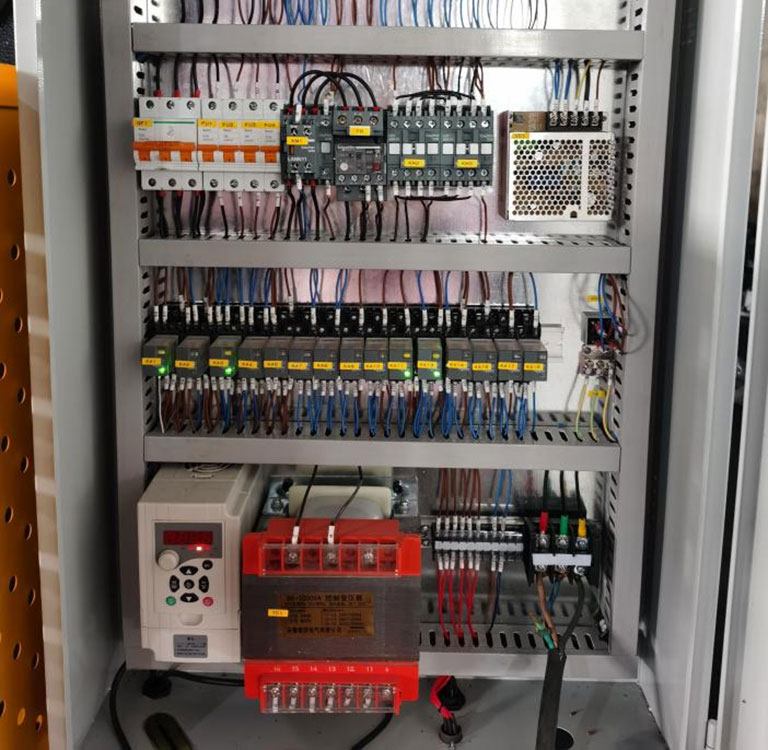

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Samples

Machine Details

Estun E21 controller system

* Backgauge control

* Control the common motor or inverter

* lntelligent positioning

* Holding pressure unloading time setting

* Workpiece counting

* 40 programs stored, 25 steps per program

* Unilateral positioning

* Concession function

* One-key backup / restore

* mm / inch

* Chinese / English

Overall welding

The whole hydraulic press brake machine adopts all-steel welding,high stability

Moulds

Optional high precision moulds,bend high quality plates

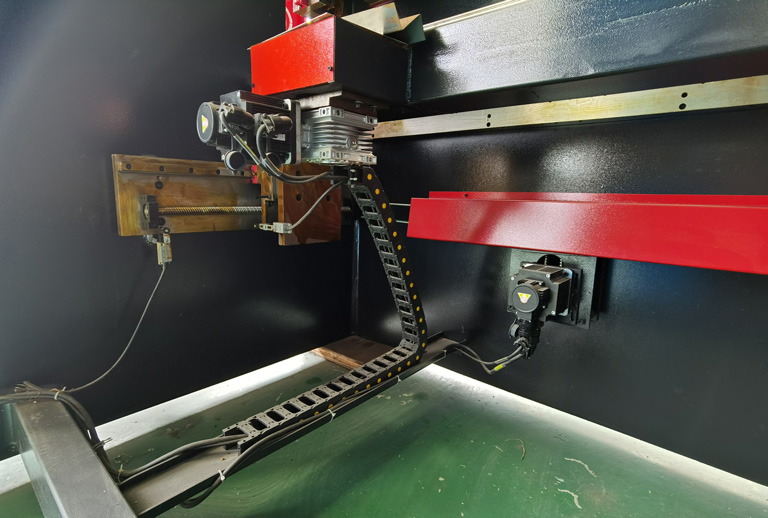

Ball screw and linear guide

has high precision, high quality,high efficient and low noise

France Schneider electrics and DELTA inverter

france schneider electrics ensure machine long life,working stability

Siemens motor servo motor

Using Siemens motor guarantee the machine service life and improve the machine working stability

Sunny pump

Using Sunny pump guarantees the oil service life with low noise working

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Quick clampings

quick clampings ensure accurate positioning and alignment

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Optional Controller System

Product detail pictures:

Related Product Guide:

That has a sound business enterprise credit rating, exceptional after-sales provider and modern producing facilities, we now have earned an superb standing amongst our buyers across the world for OEM manufacturer 60 Ton Press Brake - Hot sale WC67Y-125T/3200mm hydraulic press brake bending machine – Macro , The product will supply to all over the world, such as: Nicaragua, Rwanda, Sao Paulo, We have a good reputation for stable quality products, well received by customers at home and abroad. Our company would be guided by the idea of "Standing in Domestic Markets, Walking into International Markets". We sincerely hope that we could do business with car manufacturers, auto part buyers and the majority of colleagues both at home and abroad. We expect sincere cooperation and common development!

The company's products very well, we have purchased and cooperated many times, fair price and assured quality, in short, this is a trustworthy company!