OEM manufacturer 60 Ton Press Brake - CNC automatic 8+1 axis delem DA66T WE67K-63T/2500mm hydraulic press brake machine – Macro

OEM manufacturer 60 Ton Press Brake - CNC automatic 8+1 axis delem DA66T WE67K-63T/2500mm hydraulic press brake machine – Macro Detail:

Product Introduction

The 8+1 axis electro-hydraulic servo CNC fully automatic bending machine has a high degree of intelligence. The Y1 and Y2 axes control the strokes of the left and right cylinders to ensure that the slider runs synchronously. The Z1 and Z2 axes control the left and right movement of the two back gauge fingers. The X1、 X2 axis controls the back gauge to move back and forth, the R1 and R2 axes control the back gauge finger to move up and down, and the +1 axis is the compensation accuracy. The CNC hydraulic press brake machine adopts modern intelligent design, which is easy to operate and greatly improves the work efficiency of the machine tool. The molds of the CNC hydraulic press brake machine can choose standard molds, and also support customer specialize design molds to meet the high-precision bending requirements of different workpieces. Equipped with a high-end touch-screen CNC system imported from the Netherlands, Delem DA66T, 3D graphics simulation, simple programming, can bend various high-precision workpieces, and improve work efficiency.

Feature

1. Adopting HIWIN ball screw and linear guide rail, accuracy 0.01mm

2. Germany Bosch Rexroth hydraulic valve block

3. Germany EMB oil tube connector to prevent oil leakage

4. Germany Siemens main motor servo motor and france Schneider electrics

5. Hydraulic & electrical overload protection

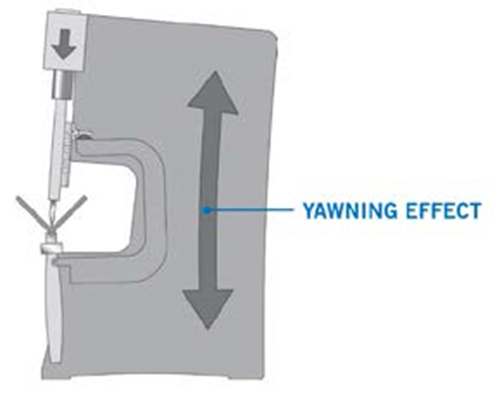

6. Automatic Mechanical compensation

7. Equipped with 8+1 axis to bend high precision workpiece

8. Laser photoelectric protection can be optional, to improve working safety

Application

Fully automatic CNC hydraulic press bake can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal,electrical power, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):2500mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):630KN |

| Motor Power(kw):5.5KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

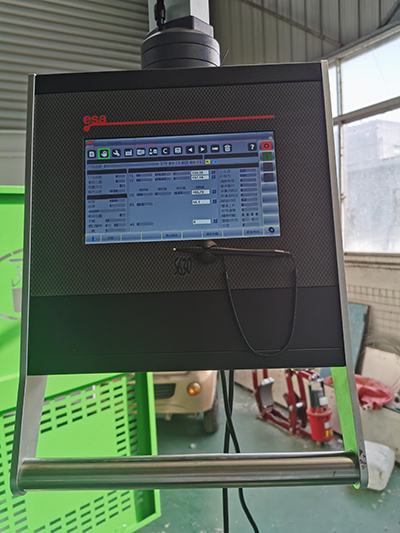

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:250mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

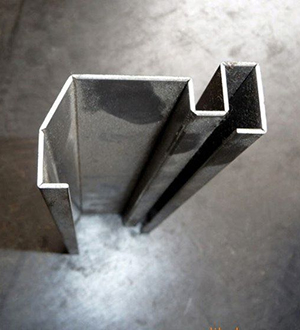

Samples

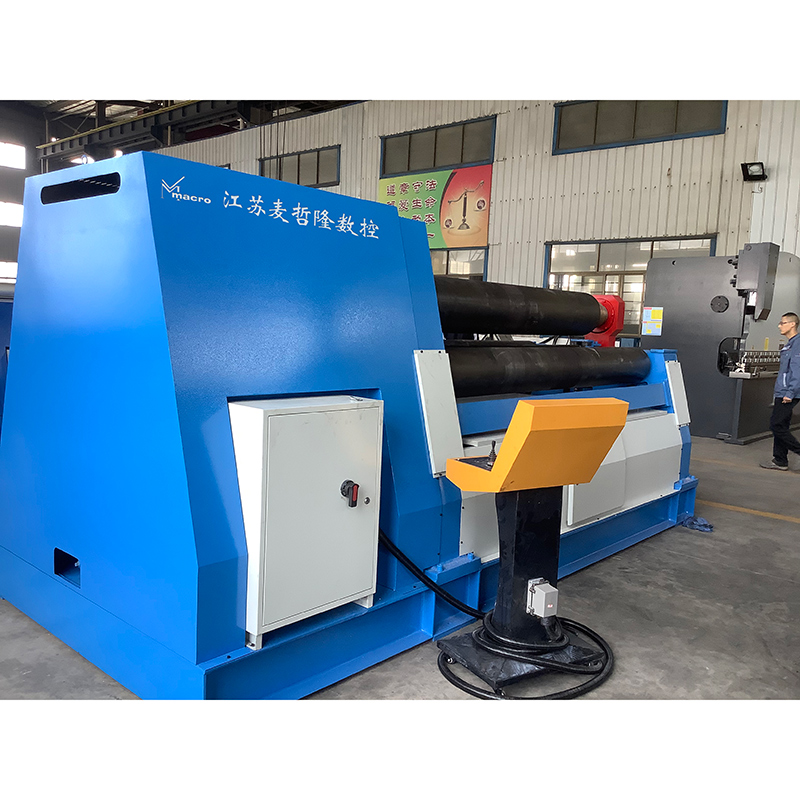

Machine Details

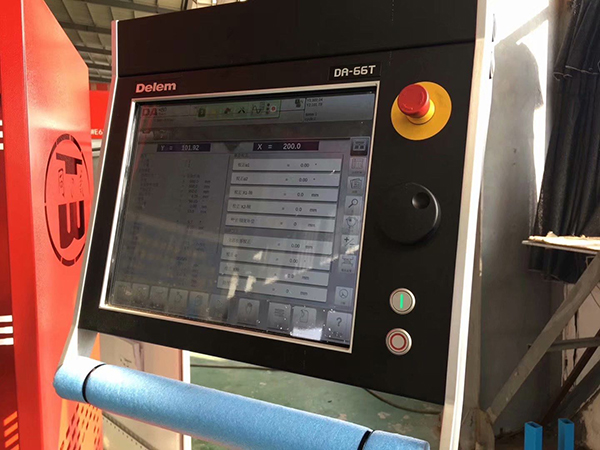

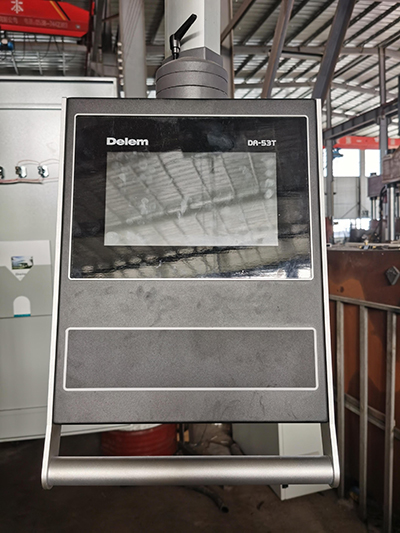

Delem DA66T Controller

● 17″ high resolution colour TFT / Full touch screen control (IR-touch)

● 2D graphical touch screen programming mode

● 3D visualisation in simulation and production

● Storage capacity 1 GB – 3D graphics acceleration

● Delem Modusys compatibility (module scalability & adaptivity)

● The basic machine control functions are Y1 + Y2 + X + R +Z1 + Z2-axis, Optionally a second back gauge axis can be used as X1 + X2 or R2 axis

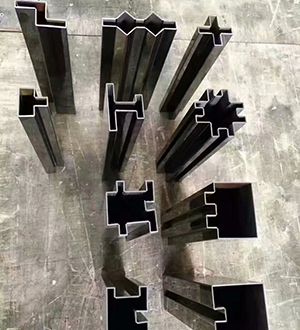

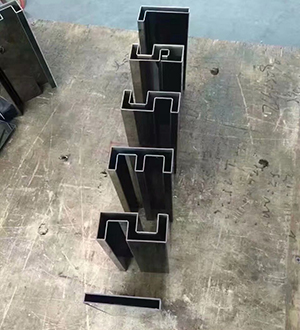

Moulds

Standard moulds or customized moulds can be optional, good wear resistance and long long life

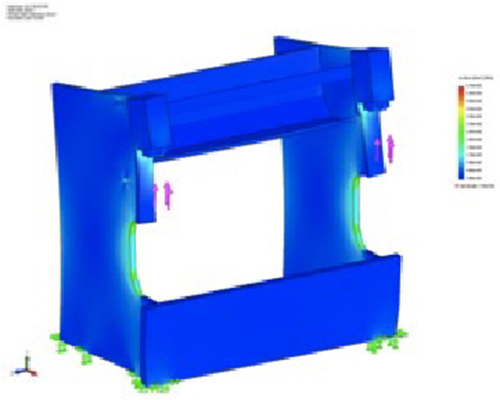

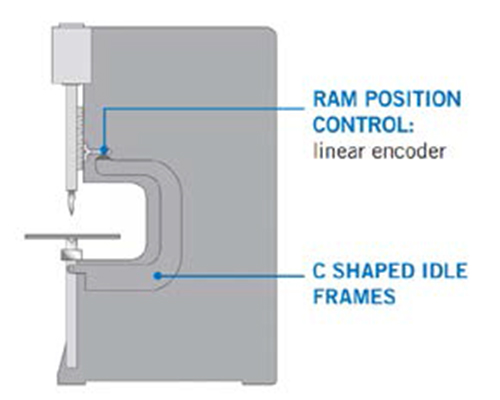

Overall welding

Overall welding has high strength,working stability

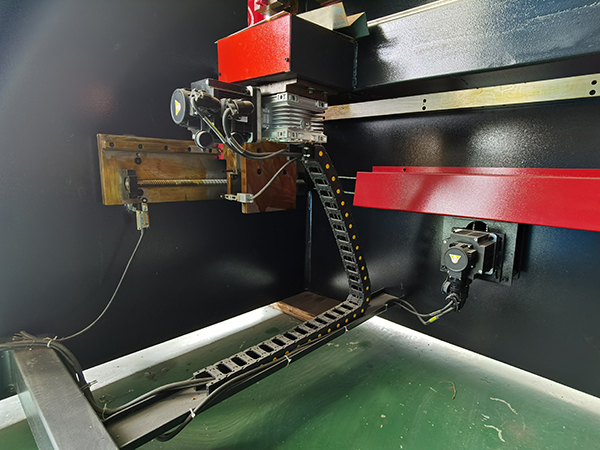

Ball screw and linear guide

Using imported ball screw and linear guide to improve backguage accuracy

Siemens motor

Using germany siemens motor guarantee machine working stability,low noise

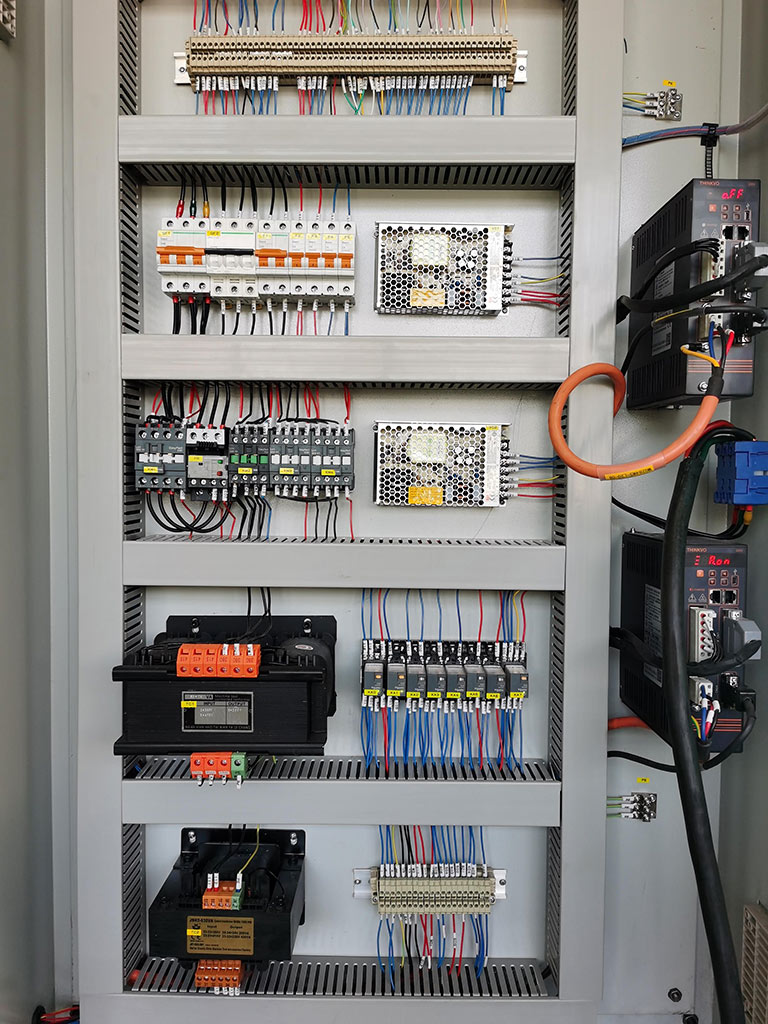

France Schneider electrics and DELTA inverter

france schneider electrics components to ensure machine working stability

Sunny pump

Using Sunny pump guarantees the oil hydraulic system working stability

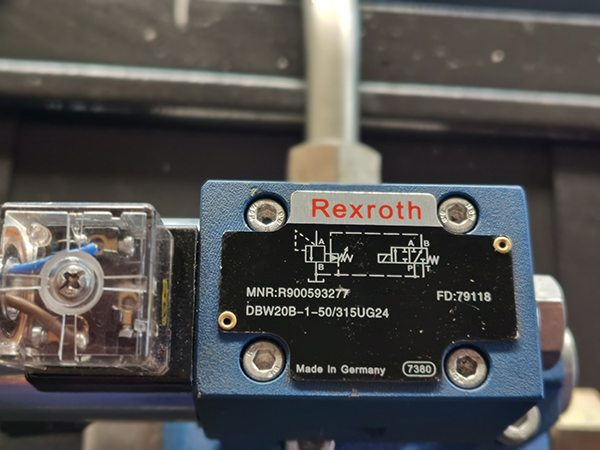

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Quick clampings

Using quick clampings can change moulds easily,easy operate

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Optional controller system

Product detail pictures:

Related Product Guide:

We thinks what clients think, the urgency of urgency to act from the interests of a purchaser position of principle, allowing for greater top quality, decrease processing costs, price ranges are much more reasonable, won the new and aged prospects the support and affirmation for OEM manufacturer 60 Ton Press Brake - CNC automatic 8+1 axis delem DA66T WE67K-63T/2500mm hydraulic press brake machine – Macro , The product will supply to all over the world, such as: Pakistan, Madrid, Cyprus, We have a dedicated and aggressive sales team, and many branches, catering to our customers. We are looking for long-term business partnerships, and ensure our suppliers that they will definitely benefit in both short and long run.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!