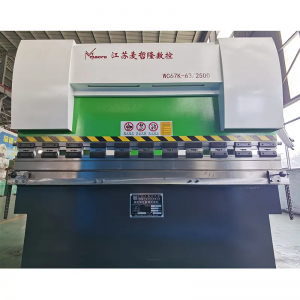

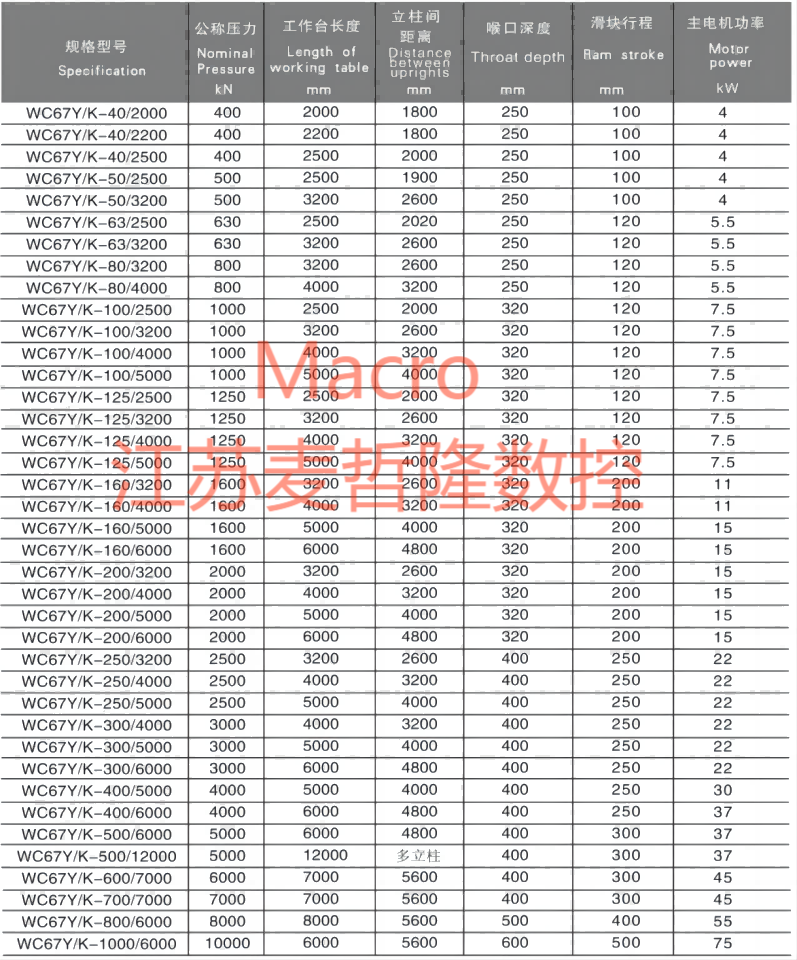

Macro high quality WE67K hydraulic 160T 3200 CNC 4+1 DA53T press brake machine

Product introduction

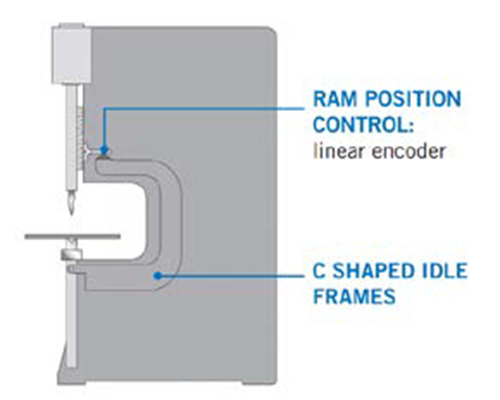

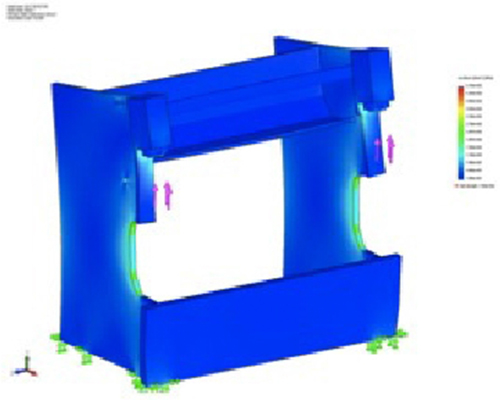

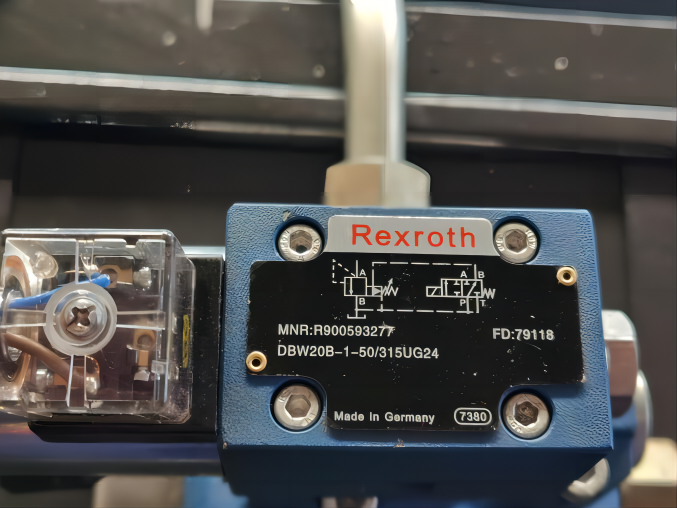

The electro-hydraulic servo CNC hydraulic press brake machine adopts servo motor as the power device, which meets the requirements of modern environmental protection and energy saving, and can process various metal workpieces with high efficiency and high precision. It adopts the overall welding structure and is equipped with a high-precision Delem DA53T numerical control system. It has the function of simulated bending and is easy to operate. The Rexroth hydraulic system imported from Germany is selected to ensure high working stability of the CNC hydrauclic press brake machine. The compensation method of the workbench can be selected from mechanical compensation or hydraulic compensation, which ensures the good straightness and bending angle of the processed workpiece. The ball screw and linear guide are selected from Taiwan HIWIN high-end configuration. The numerical control system can automatically adjust the compensation amount, which is easy to operate and has a long machine life.

Product feature

1.Fully automatic CNC hydraulic press brake machine bend sheet metal stainless steel plates,with high bending precision,high efficient,operating easy and safety

2.The welded steel structure of the whole machine ensures high precision and stability

3.Adopt Delem DA53T visual operating system,with touch-screen,multi-functions and practical,easy operating.

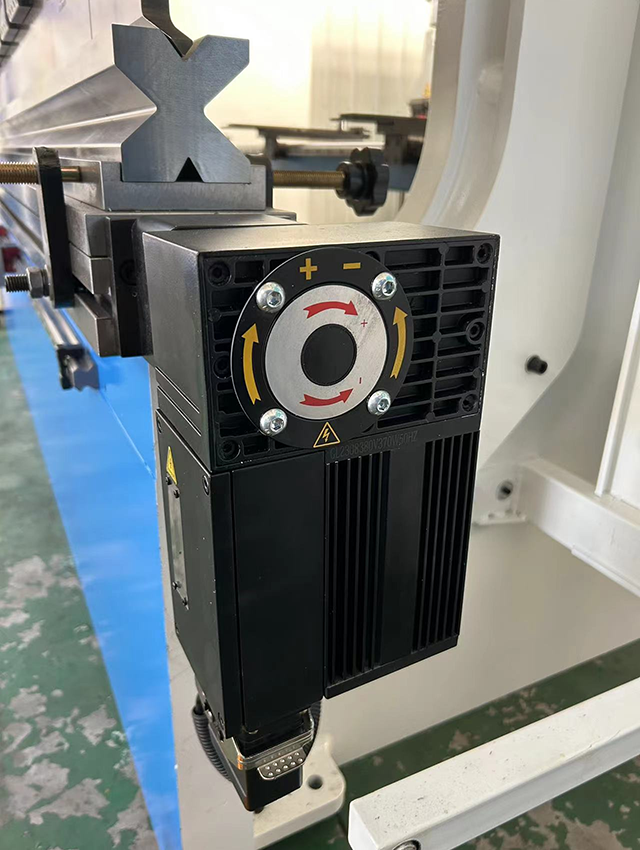

4.4+1 axis CNC backguage,high accuracy can reach ± 0.01mm

5.With germany siemens main motor,schneider electric components from france

6.Equipped with linear guide rail and HIWIN ball screw , with high accuracy, can reach 0.01mm

7.Adopt electro-hydraulic servo control system, with high performance and high precision

8.CNC hydraulic Press Brake machine toolings use 40CrMo Materials, to ensure die with hardness, ensure die have long life.

Application

Hydraulic press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Product parameter

Product details

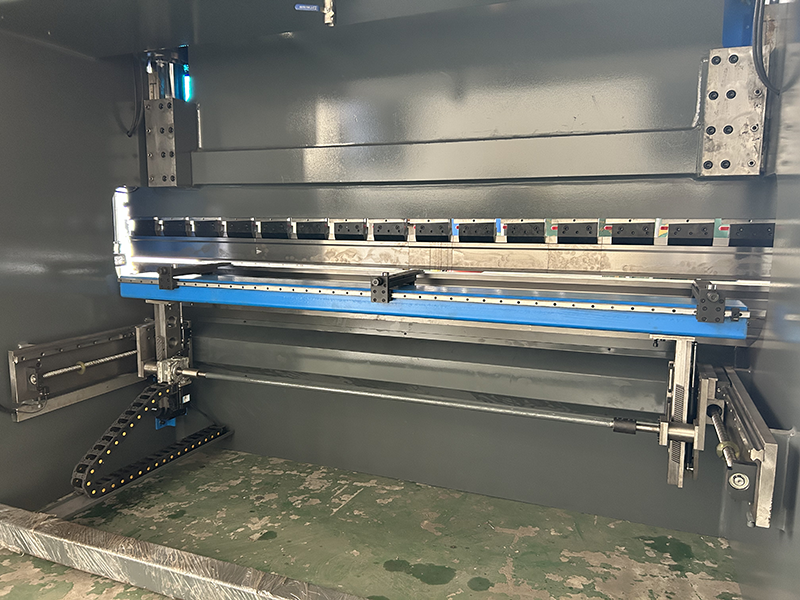

Back side

Delem DA53T CNC control system

Quick clamp

Bosch Rexroth hydraulic valve

Hydraulic pump from Sunny

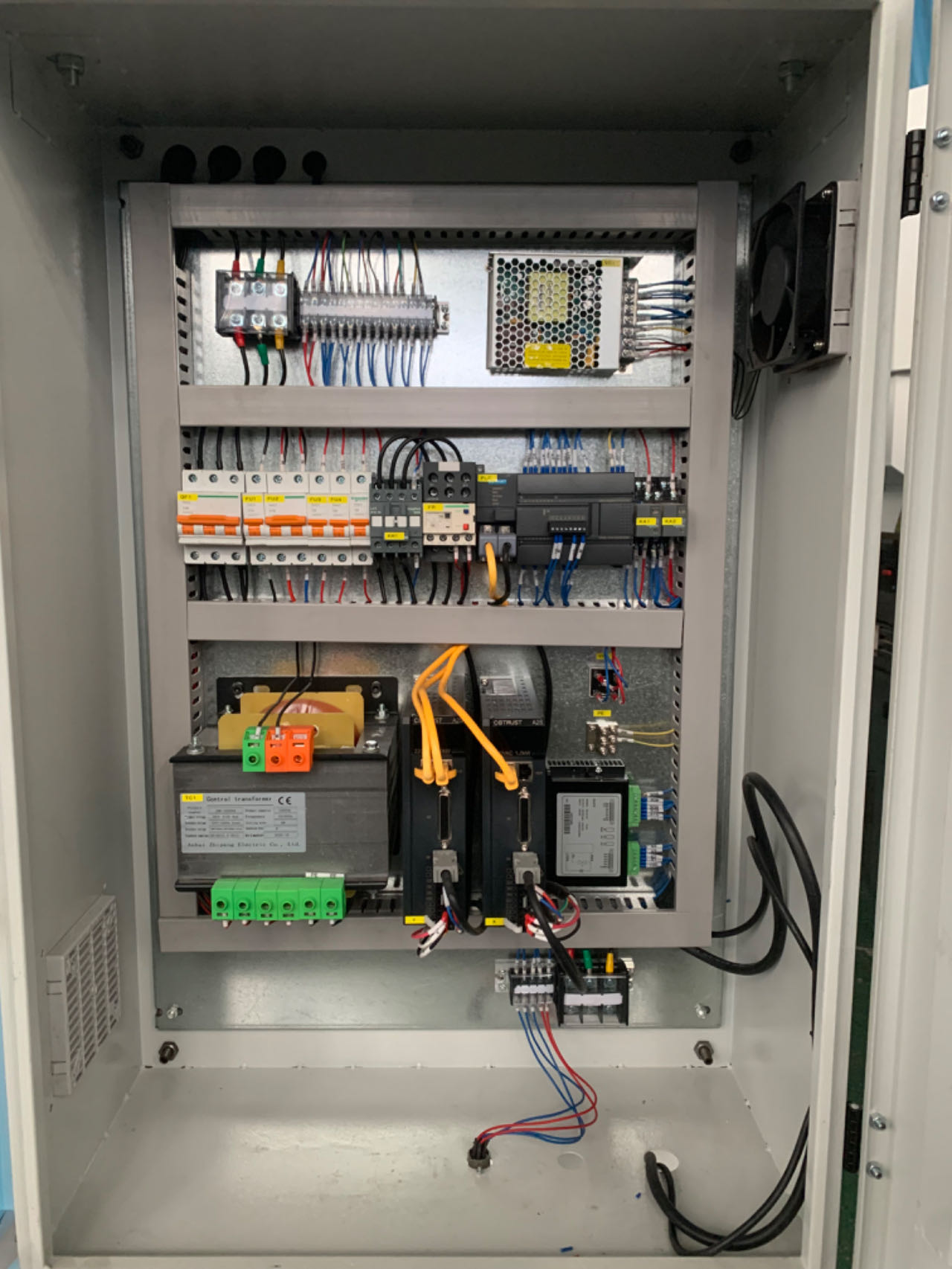

Electrical cabinet

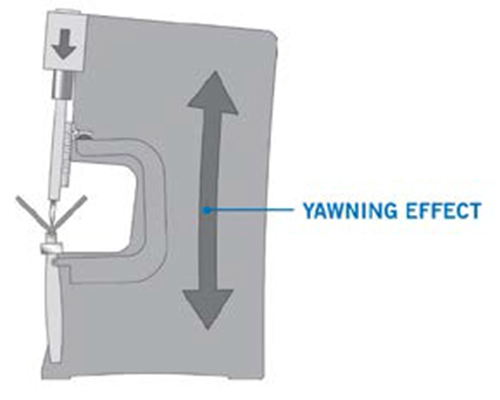

Mechanical compensation

Siemens motor

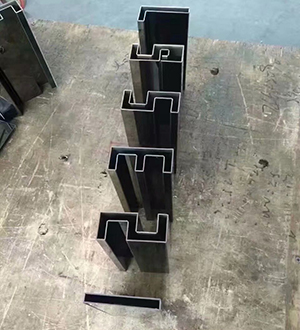

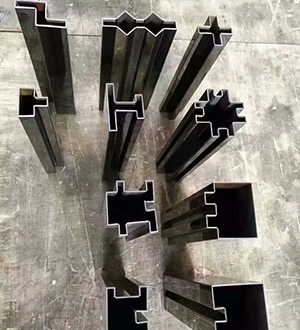

customized tool

Screw ball and linear guide

Laser protection

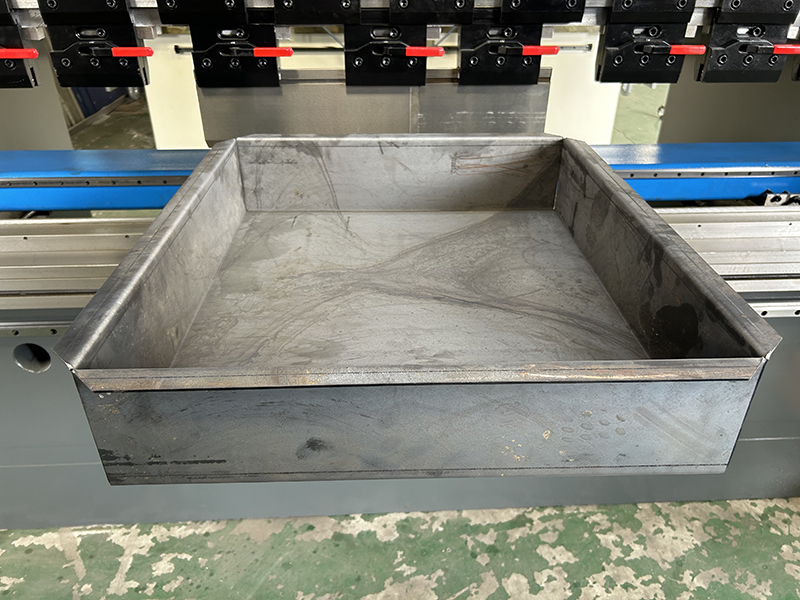

Bending workpiece

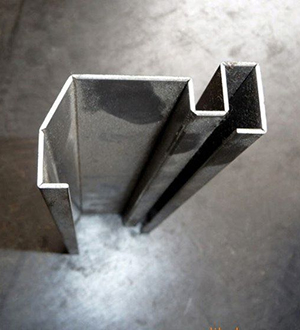

Sample :