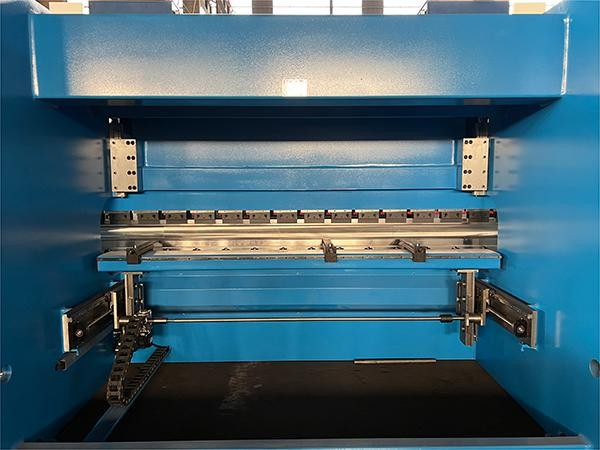

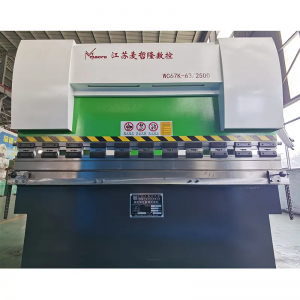

Macro high quality WE67K DSVP hydraulic 80T 3200 CNC 4+1 DA53T press brake machine

Product introduction:

The servo motor in the DSVP CNC bending machine works based on the servo control system. It receives the command signal from the CNC system and converts the electrical signal into precise mechanical movement. Specifically, the encoder

inside the servo motor will feed back the motor's position, speed and other information to the control system in real time to form a closed-loop control. In this way, the control system can continuously adjust the motor output according to the deviation between the actual movement and the command, thereby achieving high-precision control of the movement of the bending machine slider and ensuring the accuracy and stability of the bending.

It adopts the overall welding structure and is equipped with a high-precision Delem DA53T numerical control system. It has the function of simulated bending and is easy to operate. The Rexroth hydraulic system imported from Germany is selected to ensure high working stability of the CNC hydrauclic press brake machine. The compensation method of the workbench can be selected from mechanical compensation or hydraulic compensation, which ensures the good straightness and bending angle of the processed workpiece. The ball screw and linear guide are selected from Taiwan HIWIN high-end configuration. The numerical control system can automatically adjust the compensation amount, which is easy to operate and has a long machine life.

Product feature

1.The DSVP technology can automatically adjust the output flow and pressure of the oil pump according to the actual workload of the bending machine, which can save about 60% energy compared with traditional bending machines.

2.Since the oil pump output power matches the actual load, energy loss and heat generation are reduced, the oil temperature is low during operation, and the service life of the hydraulic components can be extended. At the same time, the operating noise is also greatly reduced, providing a quieter working environment.

3.High-speed and high-precision processing: Equipped with advanced CNC system and servo control technology, the slider of the DSVP CNC bending machine moves fast, can quickly complete the bending operation, and improve production efficiency. And the positioning accuracy is high, for example, the positioning accuracy of some equipment can reach ±0.01mm, ensuring the dimensional accuracy and consistency of the processed parts.

4.Fully automatic CNC hydraulic press brake machine bend sheet metal stainless steel plates,with high bending precision,high efficient,operating easy and safety

5.The welded steel structure of the whole machine ensures high precision and stability

6.Adopt Delem DA53T visual operating system,with

touch-screen,multi-functions and practical,easy operating.

7.4+1 axis CNC backguage,high accuracy can reach ± 0.01mm

8.With germany siemens main motor,schneider electric components from france

9.Equipped with linear guide rail and HIWIN ball screw , with high accuracy, can reach 0.01mm

10.Adopt electro-hydraulic servo control system, with high performance and high precision

11.CNC hydraulic Press Brake machine toolings use 42CrMo Materials, to ensure die with hardness, ensure die have long life.a

Product application

The sizes and shapes of metal structural parts and mechanical parts vary greatly, which requires high processing capabilities and adaptability of the bending machine. It needs to be able to process plates of different thicknesses and materials, and ensure the strength and precision after bending.

It can be used to manufacture the connecting parts of steel beams and steel columns in building steel structures, as well as workbenches, brackets, boxes, etc. in mechanical manufacturing. The powerful pressure output and precise control capabilities of the DSVP CNC bending machine can effectively bend thick plates and high-strength steels, meeting the strength and precision requirements of parts in the metal structure and mechanical manufacturing industries.

Product parameter

|

NO |

Spec |

Cylinder Cylinder diameter/rod

diameter(mm) |

oil pump(ml/r)

*2 |

(Servo motor + driver)*2 |

Fast down Speed(

mm/s) |

Working speed(mm/s

) |

Quick return speed(m

m/s) |

Work pressure( bar) | Fuel tank capacity

(L) |

| 1 | 63T | 120/115 | 13 | 5.5KW | 250 | 25 | 250 | 275 | 50 |

| 2 | 100T | 151/145 | 16 | 7.5KW | 280 | 25 | 250 | 275 |

63 |

| 3 | 125T | 172/165 | 16 | 7.5KW | 180 | 15 | 180 | 270 | |

| 4 | 160T | 197/190 | 16 | 7.5KW | 160 | 12 | 160 | 255 | |

| 5 | 200T | 220/210 | 20 | 9KW | 130 | 13 | 140 | 263 |

80 |

| 6 | 250T | 240/230 | 20 | 9KW | 130 | 11 | 130 | 275 | |

| 7 | 300T | 260/250 | 20 | 9KW | 120 | 9 | 120 | 285 | |

| 8 | 400T | 310/295 | 32 | 15KW+22KW | 100 | 11 | 110 | 265 | 200 |

| 9 | 500T | 350/335 | 32 | 15KW+22KW | 100 | 7 | 90 | 260 | |

|

10 |

600T | 380/360 | 40 | 19.6KW+37K

W |

100 | 8.5 | 80 | 265 |

300 |

|

11 |

800T | 430/410 | 50 | 31KW+37KW | 100 | 8 | 90 | 276 | |

|

12 |

1000T | 480/460 | 63 | 35.6KW+45K

W |

100 | 6.5 | 80 | 276 |

400 |

|

13 |

1200T | 540/510 | 63 | 35.6KW+45K

W |

100 | 6.5 | 60 | 262 | |

|

14 |

1600T | 630/600 | 100 | 60KW+75KW | 100 | 8 | 80 | 260 |

650 |

|

15 |

2000T | 700/670 | 125 | 72KW+90KW | 100 | 8 | 90 | 260 | |

|

16 |

2500T | 760/730 | 125 | 72KW+90KW | 100 | 6.5 | 80 | 275 | |

|

17 |

3000T | 835/800 | 160 | 90KW+110K

W |

100 | 7 | 80 | 275 |

1000 |

|

18 |

3600T | 915/880 | 160 | 90KW+110K

W |

100 | 6 | 80 | 275 |

Torsion-sync-CNC-Press-Brake-Machine-300x300.jpg)