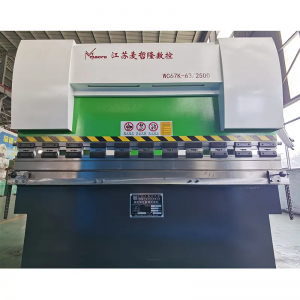

Macro high quality WC67K hydraulic 125T 2500 TP10 (XYR)Torsion-sync CNC Press Brake Machine

Product introduction

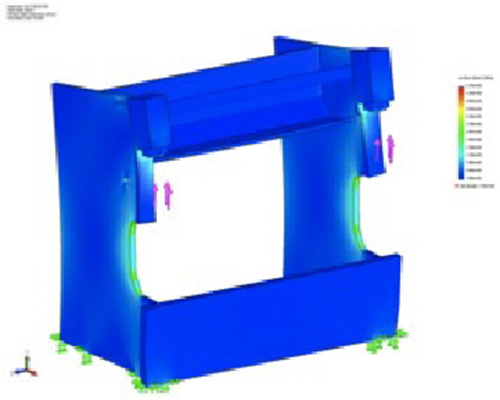

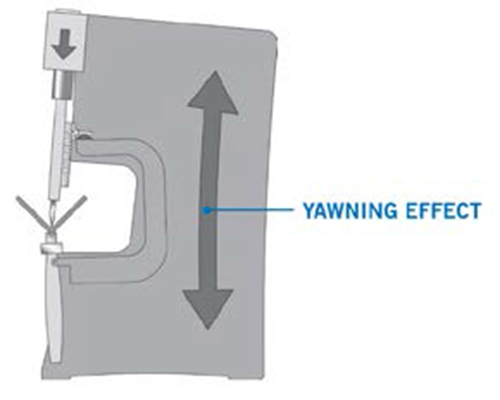

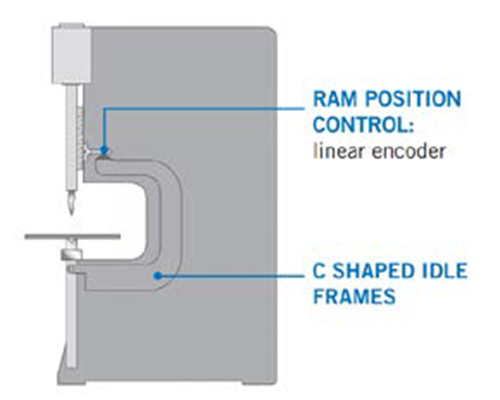

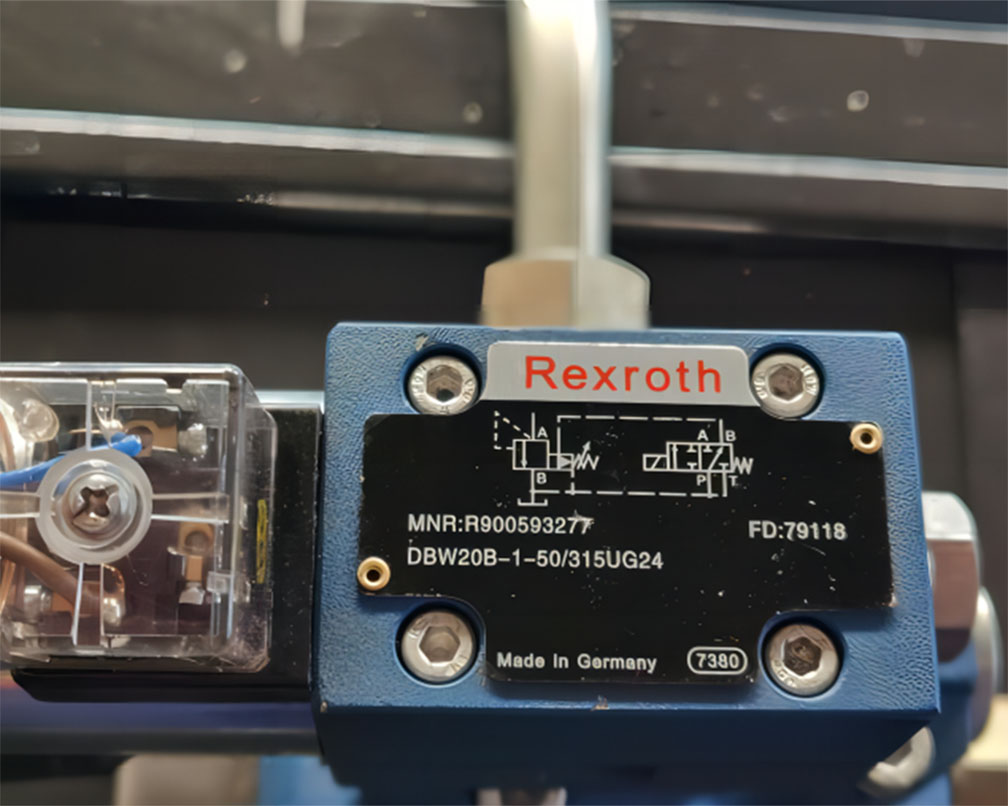

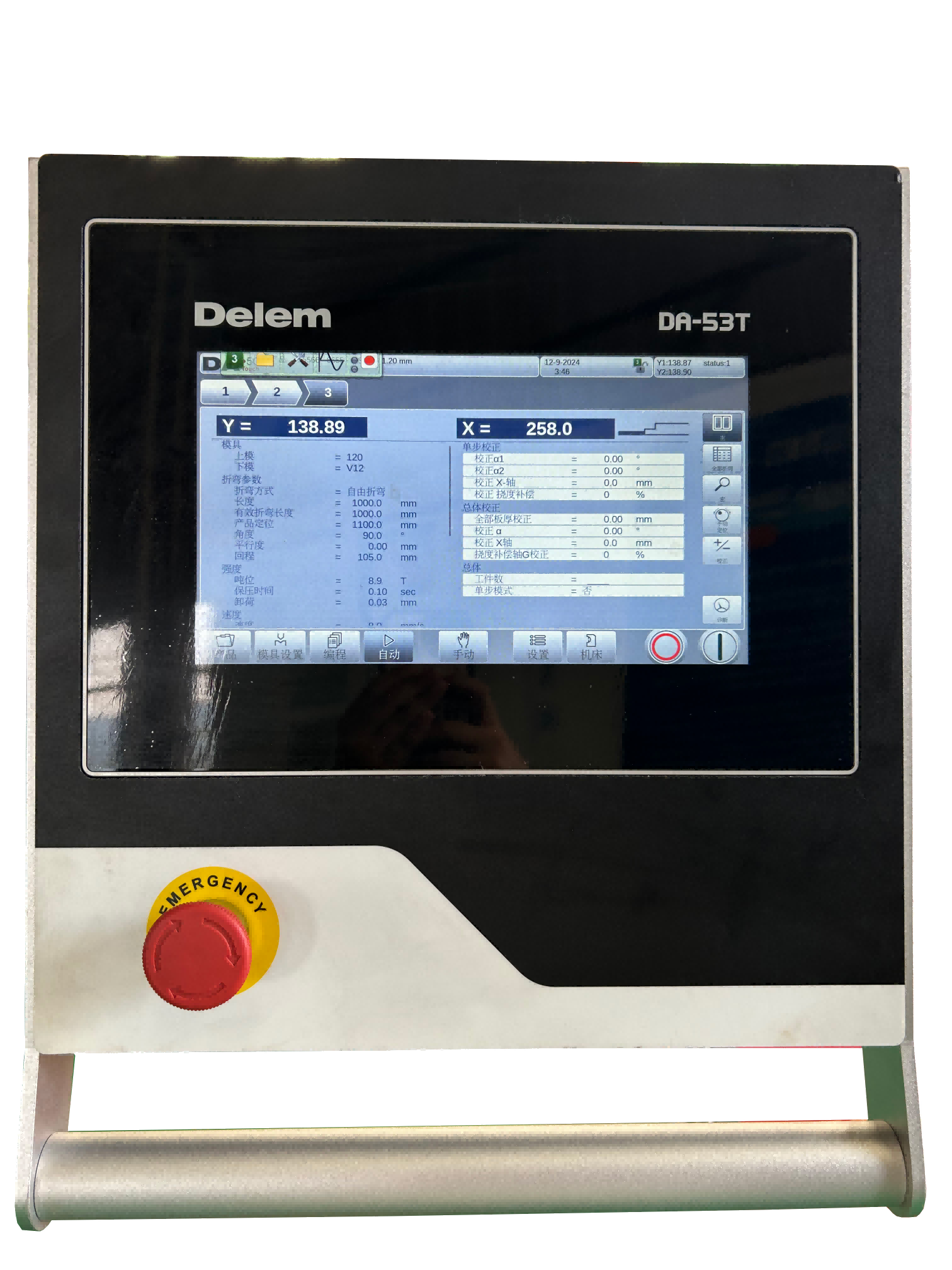

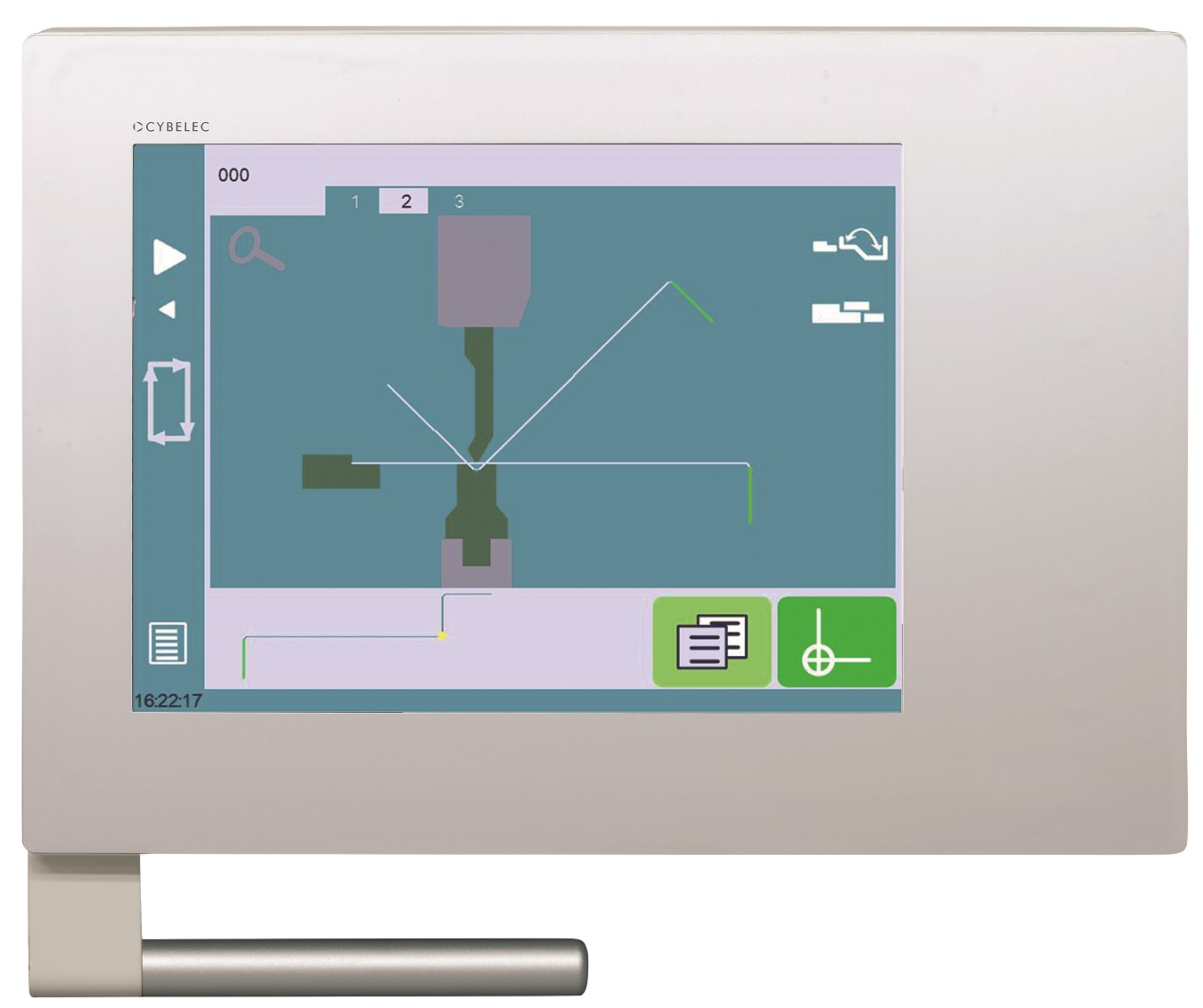

1.Totally EU streamlined design. Monobloc by welding robots & apparatus and stress relief process by annealing treatment. 2.Hydraulic top-drive, steadiness and reliability, mechanical stop, steel torsion bar to maintain synchronization, high precision. 3.Adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch Rexroth, Germany. 4.Travel limit protection, full machine guarding with safety interlocker. 5.Optional mechanical synchronous mechanism and the complex compensation are designed so as to raise the workpieces precision. 6.The stroke and distance of the back gauge is adjusted by the motor. 7.Inch, single mode being designed for the machine and reversing and maintain time can be controlled by the time relays 8.Safe fence and the electric interlocker have been designed for the machine to ensure the operation safety. 9.Standard punches and dies. Front arm material support. Foot pedal with emergency stop. 10. Control system: Estun NC E21, E22, CNC TP10 , CNC DELEM DA41,DA53T,DA56,DA58T,DA66T, ESA630, ESA640, ESA650, CYBTOUCH 12, CYBTOUCH 15…..

Product feature

1.Fully automatic CNC hydraulic press brake machine bend sheet metal stainless steel plates,with high bending precision,high efficient,operating easy and safety

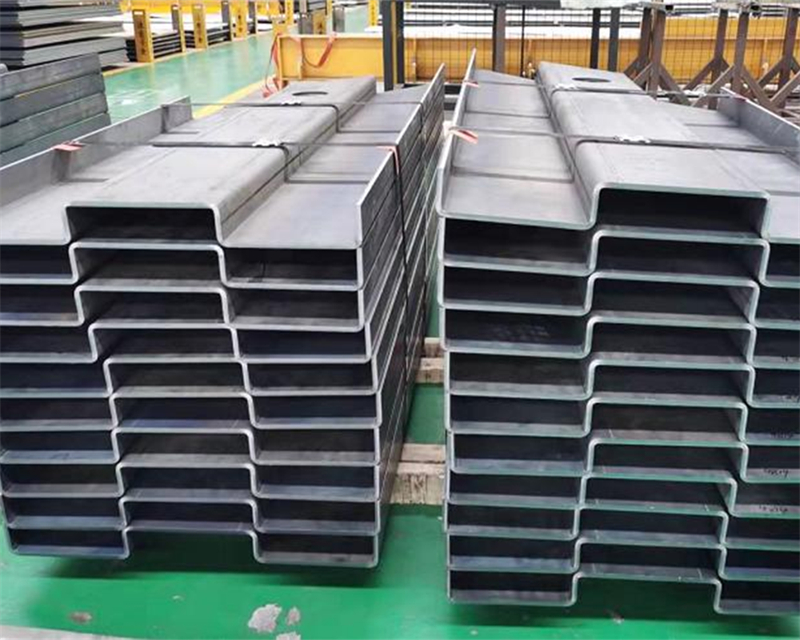

2.The welded steel structure of the whole machine ensures high precision and stability

3.Adopt TP10 visual operating system,with touch-screen,multi-functions and practical,easy operating.

5.With germany siemens main motor,schneider electric components from france

6.Equipped with linear guide rail and HIWIN ball screw , with high accuracy, can reach 0.01mm

7.Adopt servo control system, with high performance and high precision

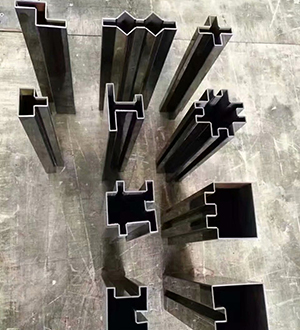

8.CNC hydraulic Press Brake machine toolings use 40CrMo Materials, to ensure die with hardness, ensure die have long life.

Product application

Hydraulic press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Product parameter

|

Specifications

|

Nominal pressure KN |

Workbench length mm |

Distance between columns mm |

Throat depth mm |

Ram stroke mm |

Motor power KW |

|

WC67Y/K-40/2000 |

400 |

2000 |

2000 |

250 |

100 |

4 |

|

WC67Y/K-40/2200 |

400 |

2200 |

2200 |

250 |

100 |

4 |

|

WC67Y/K-40/2500 |

400 |

2500 |

2500 |

250 |

100 |

4 |

|

WC67Y/K-50/2500 |

500 |

2500 |

2500 |

250 |

100 |

4 |

|

WC67Y/K-50/3200 |

500 |

3200 |

3200 |

250 |

100 |

4 |

|

WC67Y/K-63/2500 |

630 |

2500 |

2500 |

250 |

120 |

5.5 |

|

WC67Y/K-63/3200 |

630 |

3200 |

3200 |

250 |

120 |

5.5 |

|

WC67Y/K-80/3200 |

800 |

3200 |

3200 |

250 |

120 |

5.5 |

|

WC67Y/K-80/4000 |

800 |

4000 |

4000 |

250 |

120 |

5.5 |

|

WC67Y/K-100/2500 |

1000 |

2500 |

2500 |

320 |

120 |

7.5 |

|

WC67Y/K-100/3200 |

1000 |

3200 |

3200 |

320 |

120 |

7.5 |

|

WC67Y/K-100/4000 |

1000 |

4000 |

4000 |

320 |

120 |

7.5 |

|

WC67Y/K-100/5000 |

1000 |

5000 |

5000 |

320 |

120 |

7.5 |

|

WC67Y/K-125/2500 |

1250 |

2500 |

2500 |

320 |

120 |

7.5 |

|

WC67Y/K-125/3200 |

1250 |

3200 |

3200 |

320 |

120 |

7.5 |

|

WC67Y/K-125/4000 |

1250 |

4000 |

4000 |

320 |

120 |

7.5 |

|

WC67Y/K-125/5000 |

1250 |

5000 |

5000 |

320 |

120 |

7.5 |

|

WC67Y/K-160/3200 |

1600 |

3200 |

3200 |

320 |

200 |

11 |

|

WC67Y/K-160/4000 |

1600 |

4000 |

4000 |

320 |

200 |

11 |

|

WC67Y/K-160/5000 |

1600 |

5000 |

5000 |

320 |

200 |

15 |

|

WC67Y/K-160/6000 |

1600 |

6000 |

6000 |

320 |

200 |

15 |

|

WC67Y/K-200/3200 |

2000 |

3200 |

3200 |

320 |

200 |

15 |

|

WC67Y/K-200/4000 |

2000 |

4000 |

4000 |

320 |

200 |

15 |

|

WC67Y/K-200/5000 |

2000 |

5000 |

5000 |

320 |

200 |

15 |

|

WC67Y/K-200/6000 |

2000 |

6000 |

6000 |

320 |

200 |

15 |

|

WC67Y/K-250/3200 |

2500 |

3200 |

3200 |

400 |

250 |

22 |

|

WC67Y/K-250/4000 |

2500 |

4000 |

4000 |

400 |

250 |

22 |

|

WC67Y/K-250/5000 |

2500 |

5000 |

5000 |

400 |

250 |

22 |

|

WC67Y/K-300/4000 |

3000 |

4000 |

4000 |

400 |

250 |

22 |

|

WC67Y/K-300/5000 |

3000 |

5000 |

5000 |

400 |

250 |

22 |

|

WC67Y/K-300/6000 |

3000 |

6000 |

6000 |

400 |

250 |

22 |

|

WC67Y/K-400/5000 |

4000 |

5000 |

5000 |

400 |

250 |

30 |

|

WC67Y/K-400/6000 |

4000 |

6000 |

6000 |

400 |

250 |

37 |

|

WC67Y/K-500/6000 |

5000 |

6000 |

6000 |

400 |

300 |

37 |

|

WC67Y/K-500/12000 |

5000 |

12000 |

12000 |

400 |

300 |

37 |

|

WC67Y/K-600/7000 |

6000 |

7000 |

7000 |

400 |

300 |

45 |

|

WC67Y/K-700/7000 |

7000 |

7000 |

7000 |

400 |

300 |

45 |

|

WC67Y/K-800/6000 |

8000 |

8000 |

8000 |

500 |

400 |

55 |

|

WC67Y/K-1000/6000 |

10000 |

6000 |

6000 |

600 |

500 |

75 |

Product details

Back side

Screw ball and linear guide

TP10 CNC control system

Electrical cabinet(Schneider Electric)

Quick clamp ,safety light curtain

Bosch Rexroth hydraulic valve

Hydraulic pump from Sunny

Siemens motor

Standard tool

Foot switch

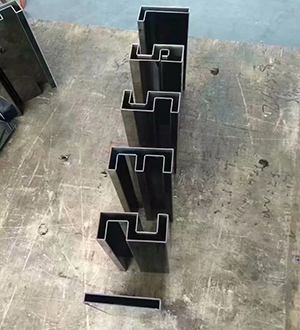

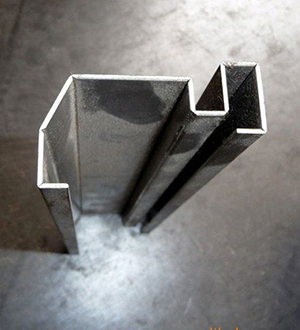

Sample

Optional controller:

Delem DA53T

Cybelec CT12

ESA630

ESA640

E300P/E310P

MT15

Delem DA66T

Delem DA69T

Cybelec Vistouch-Pac (VP88)

Cybelec CT15

Torsion-sync-CNC-Press-Brake-Machine.jpg)

Torsion-sync-CNC-Press-Brake-Machine-300x300.jpg)

Torsion-sync-CNC-Press-Brake-Machine1-300x300.jpg)

Torsion-sync-CNC-Press-Brake-Machine2-300x300.jpg)