High precision QC12Y-6X2500mm hydrauclic sheet metal shearing machine

Product Introduction

The hydraulic pendulum shearing machine is easy to operate, the upper blade is fixed on the knife holder, and the lower blade is fixed on the worktable. A material support ball is installed on the worktable to ensure that the sheet slides on it without being scratched. The back gauge can be used for the positioning of the sheet, and the position can be adjusted by the motor. The pressing cylinder on the hydraulic shearing machine can press the sheet material to ensure that it does not move when cutting the sheet material. Guardrails are installed for safety. The return trip can be adjusted by nitrogen, with fast speed and high stability.

Feature

1.Steel plate welded structure, hydraulic transmission, nitrogen cylinder return

2.Equipped with Eutun E21 controller system,easy operation, reliable performance, beautiful appearance

3.Equipped with safety protection fence to ensure safety

4.Easy blade clearance adjustment, with high precision

5.Hydraulic shearing machine blades have a long service life

6.Back gauge adjustment with high precision

7.Equipped with germany siemens motor, work stability

8.Cut plates smoothly,with high accuracy

Application

Hydraulic shearing machine are widely used in sheet metal manufacturing, aviation, light industry, metallurgy, chemical industry, construction, marine, automotive, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment.

Parameter

| Max cutting width(mm):2500mm | Max cutting thickness(mm):6mm |

| Automatic level: automatic | Condition: new |

| Brand name: Macro | Power(KW):7.5 |

| Voltage:220V/380V/400V/480V/600V | Warranty: 1 year |

| Certification: Ce and ISO | Key selling points: high efficiency and high accuracy |

| After sale service: free spare parts,field installation,commissioning and training,field maintenance and repair service,online and video technical support | Controller system: E21S |

| Applicable industries:Hotels,Machinery repair shops,construction works,energy and mining, | Electrical components: Schneider |

| Color: according customer choose | Valve: Rexroth |

| Sealing rings:Volqua Japan | Motor: Siemens |

| Hydraulic oil: 46# | Pump: sunny |

| Application: Mild carbon,stainless steel or iron sheet | Inverter: DELTA |

Machine Details

E21 NC controller

HD LCD display, with both Chinese and English language options

■ Backgauge control:Smart positioning, can also be manually adjusted by hand positioning device.

■ Cut Stroke: Built-in shearing time relay

■ Shear angle: Built-in shear angle adjustment function, eliminating the angle indicators and buttons

■ Blade gap: encoder feedback, time display blade gap size

■ Having a key parameter backup and restore function

■ All keys on the panel are micro-switches.

Blade clearance adjustment

Adjust the blade clearance to ensure cutting accuracy

Overall welding

Overall welding structure,with high mechanical strength

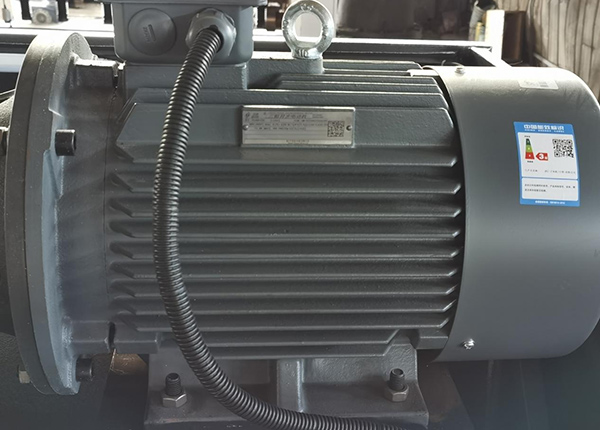

Siemens motor

Using siemens motor guarantee the machine service life,good for hydraulic system running

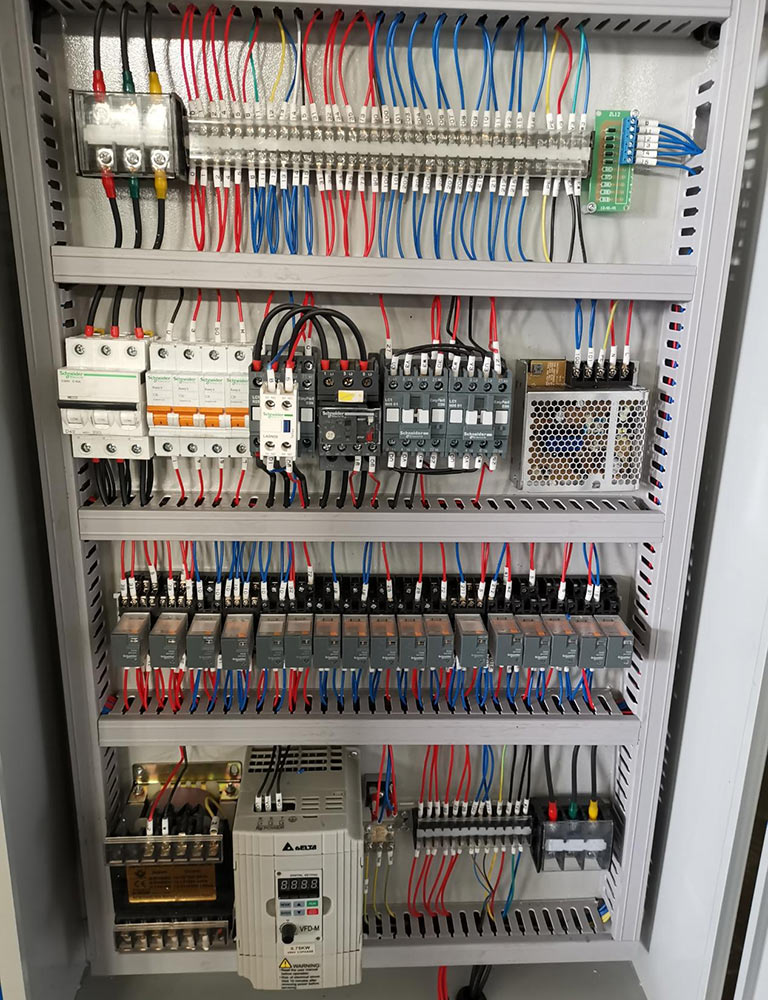

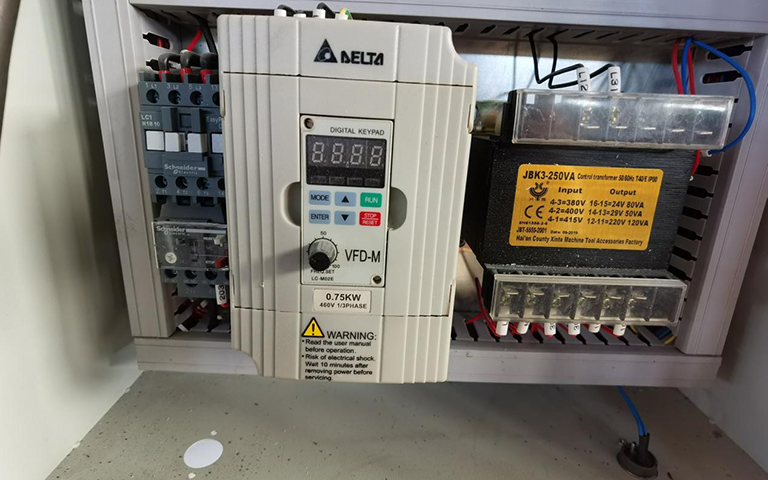

Schneider electrical components and DELTA inverter

Stable france schneider electrics, with DELTA inverter to ensure the machine working stablility and make machines have long life

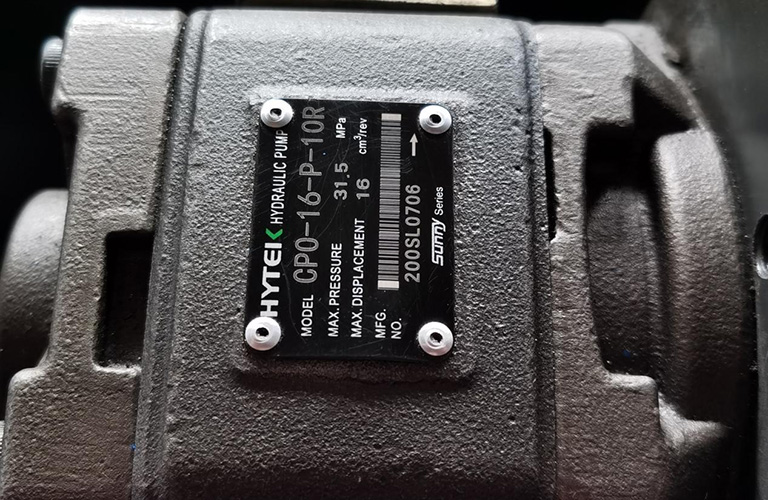

America sunny oil pump

Using USA sunny oil pump guarantees the oil service life to provide great power for the hydraulic system

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Built in spring pressure cylinder

Made by high-quality alloy tool steel , the machine can meet the impacting load and high wear resistance requirements when working