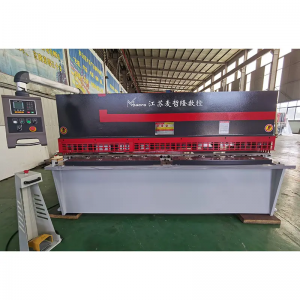

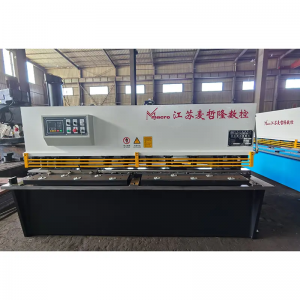

High precision QC12Y-4X2500mm hydrauclic sheet metal shearing machine

Product Introduction

Hydraulic swing beam shearing machine is a machine that cuts metal sheets of various thicknesses through a moving upper blade and a fixed lower blade with a reasonable blade gap. It is generally composed of a frame, a pressing mechanism, a blade gap adjustment device, a tool holder, and a hydraulic system. High-precision shears are equipped with imported Siemens motors, Rexroth valves, sunny pumps, Schneider electrical components and other high-end accessories. Swing type tool rest, high strength of the whole machine, return of the accumulator cylinder, easy adjustment of the blade gap, the whole machine adopts all-steel welded structure, with sufficient strength and rigidity, and easy to operate. According to the thickness of shearing, the blade gap and shearing angle can be adjusted. The blade has a long service life, can cut metal sheet plates smoothly.

Feature

1. Hydraulic transmission, pendulum tool rest, the overall welding of the frame is sturdy and durable, and the return stroke of the accumulator cylinder is stable and fast.

2. The gap between the upper and lower blades is adjusted by the handle, and the uniformity of the blade gap is easy to adjust.

3. The protective grille and electrical interlock ensure safe operation.

4. All machines satisfy ISO/CE high standard,are epuipped with best configurations.

5. Numerical control system Estun E21 controller system of special shearing machine for back gauge.

6. The rolling support device can not only reduce the frictional resistance, but also ensure that the surface of the workpiece is not scratched.

7. All-steel welded structure, vibration to eliminate stress, high strength and good rigidity.

8. Hydraulic upper transmission type, stable and reliable

Application

Hydraulic shearing machine are widely used in sheet metal manufacturing, aviation, light industry, metallurgy, chemical industry, construction, marine, automotive, electric power, electrical appliances, decoration and other industries to provide special machinery and complete sets of equipment.

Parameter

| Max cutting width(mm):2500mm | Max cutting thickness(mm):4mm |

| Automatic level: automatic | Condition: new |

| Brand name: Macro | Power(KW):4 |

| Voltage:220V/380V/400V/480V/600V | Warranty: 1 year |

| Certification: Ce and ISO | Key selling points: high efficiency and high accuracy |

| After sale service: free spare parts,field installation,commissioning and training,field maintenance and repair service,online and video technical support | Controller system: E21S |

| Applicable industries:Hotels,Machinery repair shops,construction works,energy and mining, | Electrical components: Schneider |

| Color: according customer choose | Valve: Rexroth |

| Sealing rings:Volqua Japan | Motor: Siemens |

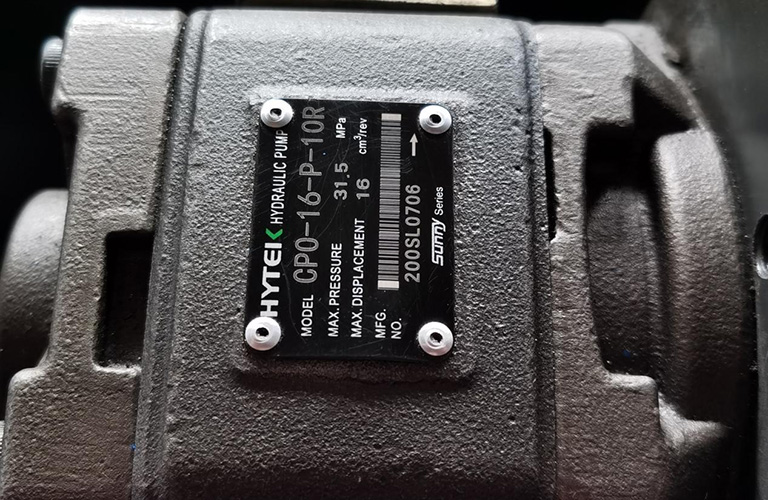

| Hydraulic oil: 46# | Pump: sunny |

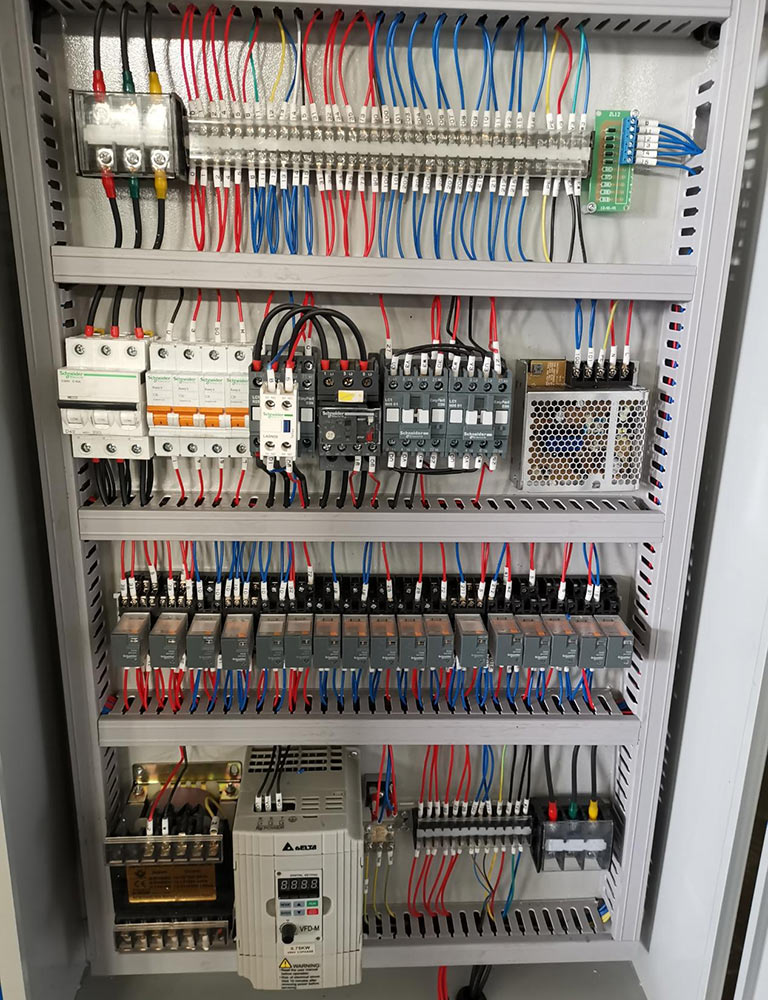

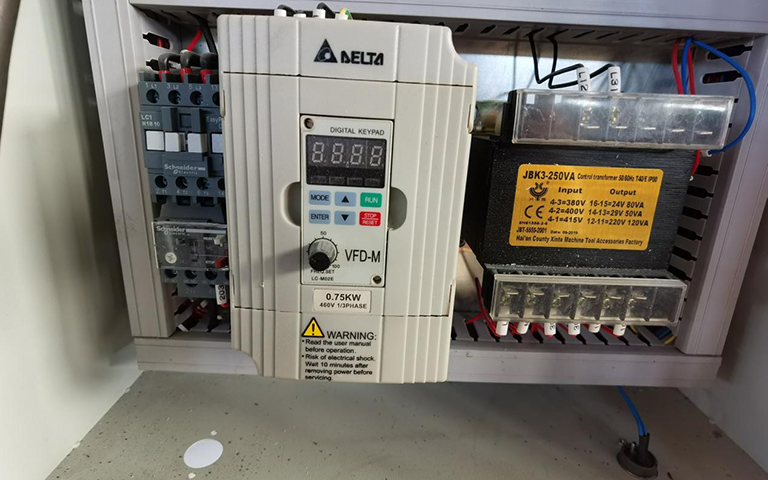

| Application: Mild carbon,stainless steel or iron sheet | Inverter: DELTA |

Machine Details

E21 NC controller

● Position display of backgauge(X-axes), resolution in 0.1mm or 0.01mm

● Backgauge and Block Control

● Control for general AC motors,frequency inverter

● Intelligent positioning

● Stock Counter

● One key backup / restore of parameters

Blade clearance adjustment

Adjust the cutting blade gap by motor according the thickness of the plate, which can get better cutting performance

Overall welding

Adopt overall welding, has high strength,has long life

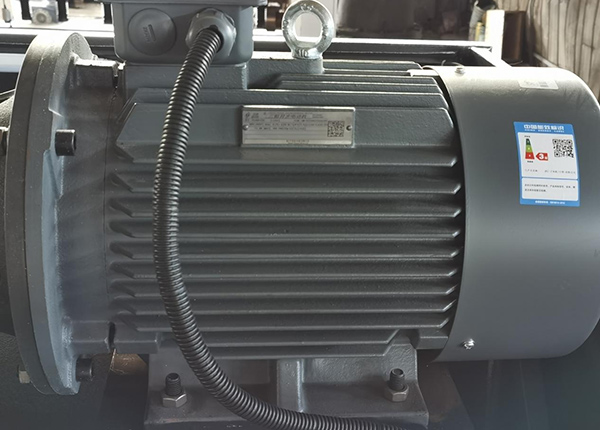

Siemens motor

Using Siemens motor guarantee the machine service life and reduce the noise when working

Schneider electrical components and DELTA inverter

Stable france schneider electrics, with DELTA inverter to ensure the machine working stablility and make machines have long life

America sunny oil pump

Using USA sunny oil pump guarantees the oil service life, and reduce the noise when working, provides great power for the hydraulic system

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Built in spring pressure cylinder

It's lower end equipped with special meterial gasket,separately control the pressure,protect the blade