Factory Promotional 102 Press Brake Machines - High precision WC67Y-250T/5000mm hydraulic press brake machine – Macro

Factory Promotional 102 Press Brake Machines - High precision WC67Y-250T/5000mm hydraulic press brake machine – Macro Detail:

Product Introduction

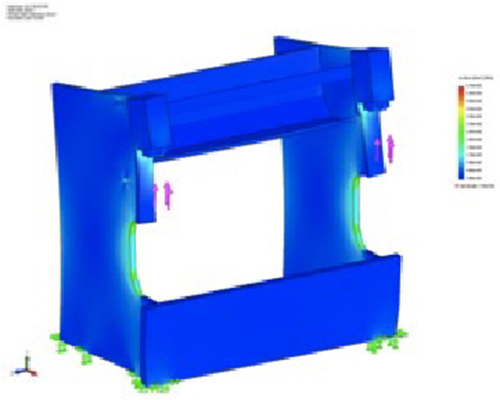

The frame of the hydraulic bending machine is processed after welding to ensure high strength, high precision and high rigidity. The mechanical synchronization system is adopted, and the two sides of the slider are moved in parallel through the synchronization shaft. Equipped with upper mold deflection compensation device, and optional fast upper mold clamping device. The back gauge of the hydraulic press brake machine has high precision, and the adjustment includes electric quick adjustment and manual fine adjustment, and the operation is simple. The X-axis back gauge is driven by siemens motor, driven by a ball screw, guided by a linear guide rail, and the stroke of the Y-axis slider is controlled by siemens motor to ensure high positioning accuracy. The configured Estun E21 controller system can efficiently control the operation of X-axis and Y-axis to ensure high bending accuracy.

Feature

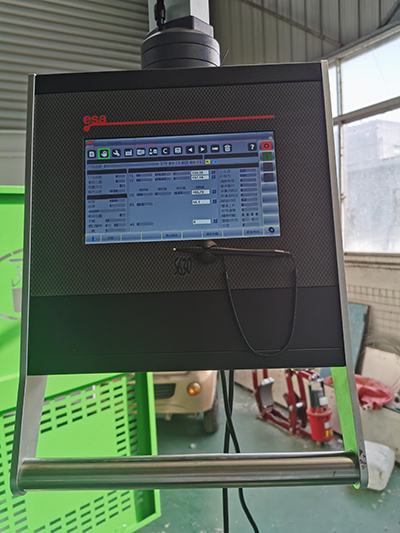

1.With high performance Estun E21 controller system

2.Equipped with high-strength all-steel welded structure

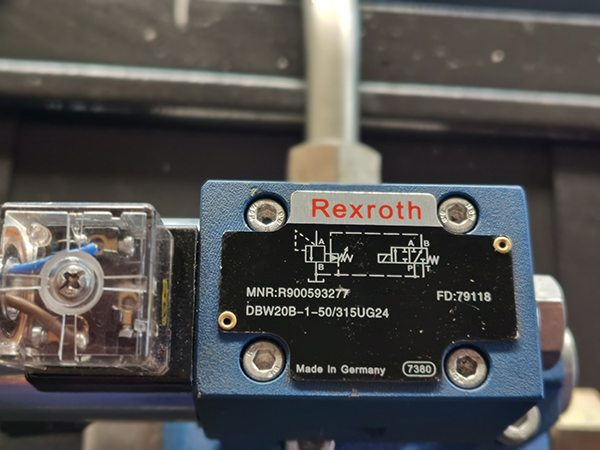

3.With germany bosch rexroth valve hydraulic system

4.Standard moulds, specialized moulds can be choosed

5.With stability schneider electric components

6.High-precision back gauge accurately locates the X-axis

7.With best quality siemens motor,sunny oil pump

8.Satisfy ISO/CE high standard

Application

Hydraulic press bake bending macine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized

|

Length of working table(mm):5000mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):2500KN |

| Motor Power(kw):22KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:400mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

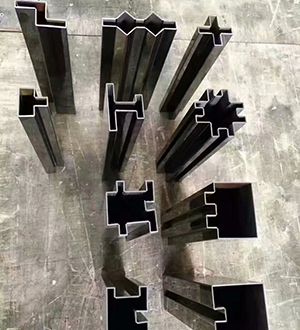

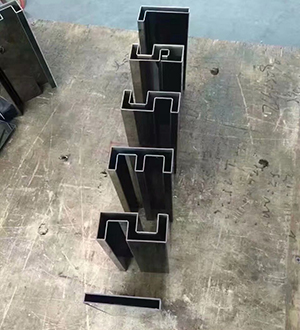

Samples

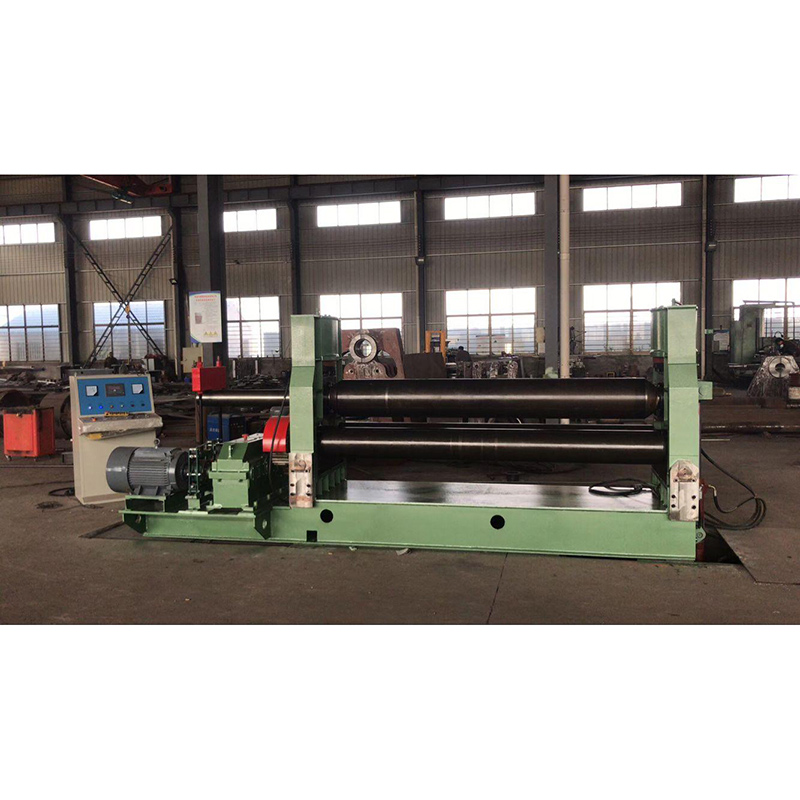

Machine Details

Estun E21 controller system

● HD LCD Display

● Rear backgauge position display

● 40 groups of program storage, each program has 25 steps

● Workpiece count function

● One-click backup/parameter restore

● The unit is mm/inch, Chinese and English

Moulds

High strength moulds bend all sizes of high precision workpiece

Overall welding

The frame adopts all-steel welded structure with good stability

Ball screw and linear guide

High stability,long life,high efficiency

Siemens motor

Using Siemens motor energy saving, guarantee the machine service life

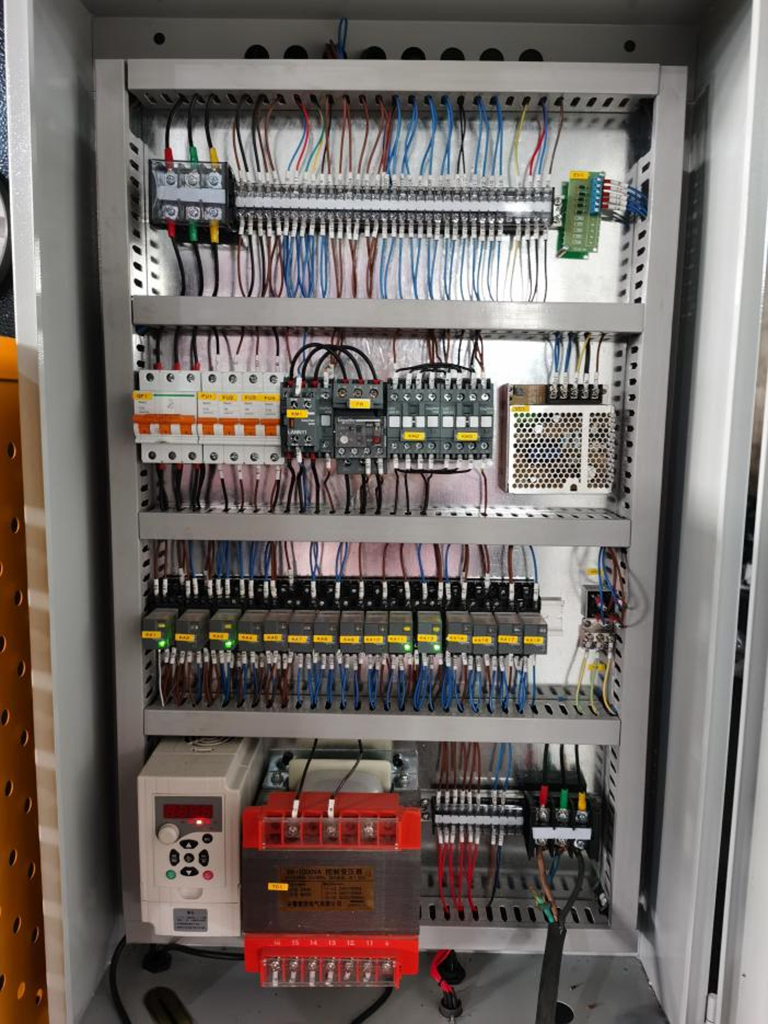

France Schneider electrics and DELTA inverter

Stable france schneider electrics to uarantee the positioning accuracy of X,Y axies with high precision

Sunny pump

Using Sunny pump perform well,provide power for hydraulic system

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

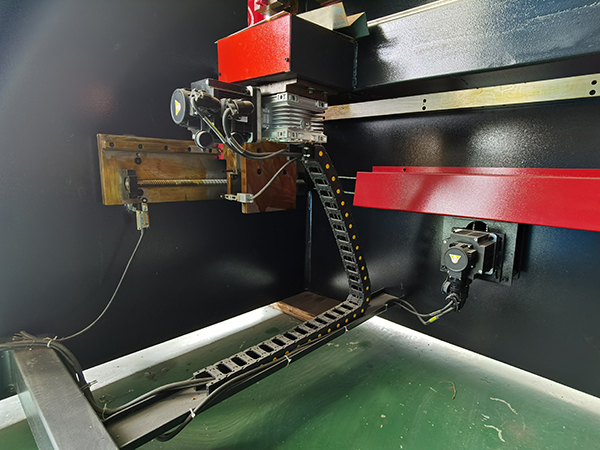

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Quick clampings

Using mechanical fast clamp for fast replacement of top punch dies.

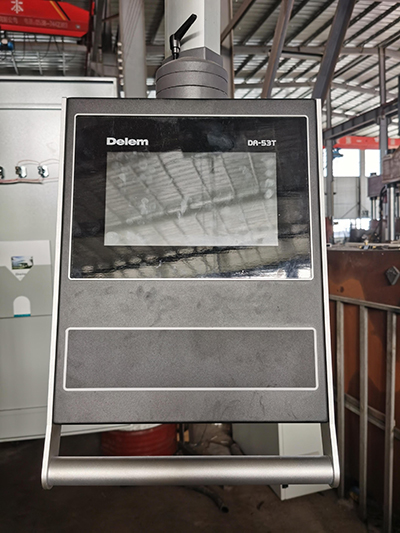

Optional controller system

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation" is our business philosophy which is frequently observed and pursued by our business for Factory Promotional 102 Press Brake Machines - High precision WC67Y-250T/5000mm hydraulic press brake machine – Macro , The product will supply to all over the world, such as: Austria, Russia, Singapore, Upon today, we've customers from all over the world, including USA, Russia, Spain, Italy, Singapore, Malaysia, Thailand, Poland, Iran and Iraq. The mission of our company is to provide the highest quality products with best price. We've been looking forward to doing business with you.

The company's products can meet our diverse needs, and the price is cheap, the most important is that the quality is also very nice.