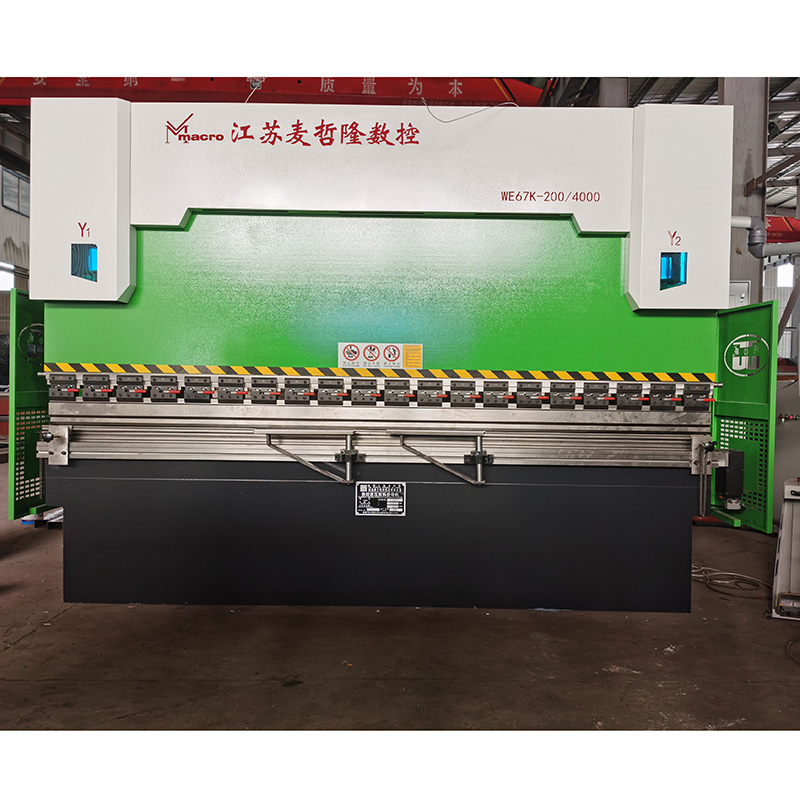

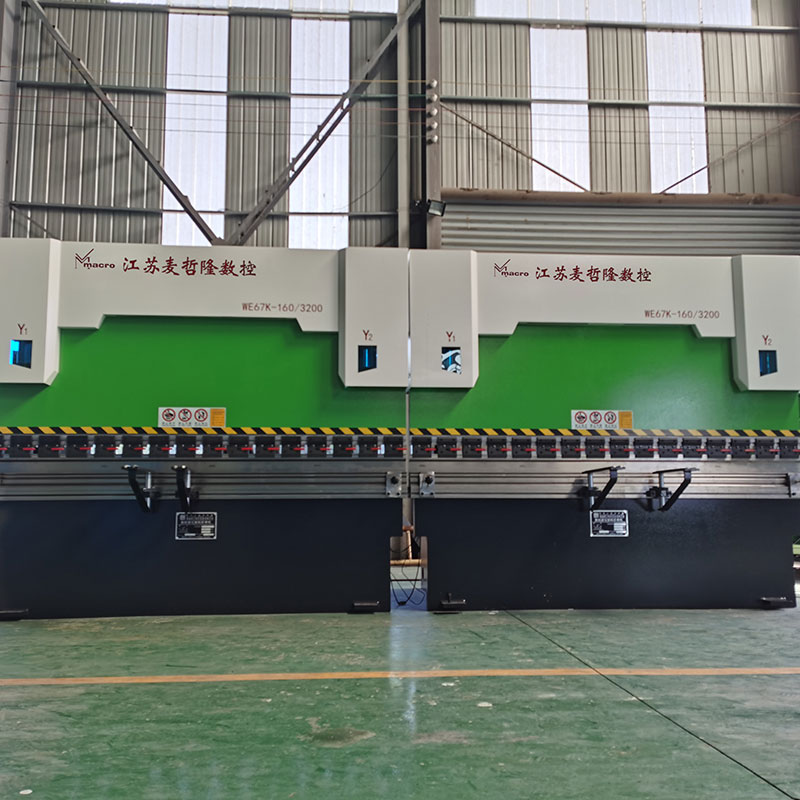

Factory Price 48 Top 10 Press Brake Manufacturers - WE67K-2X160/3200mm CNC Delem DA53T controller tandem hydraulic press brake bending machine – Macro

Factory Price 48 Top 10 Press Brake Manufacturers - WE67K-2X160/3200mm CNC Delem DA53T controller tandem hydraulic press brake bending machine – Macro Detail:

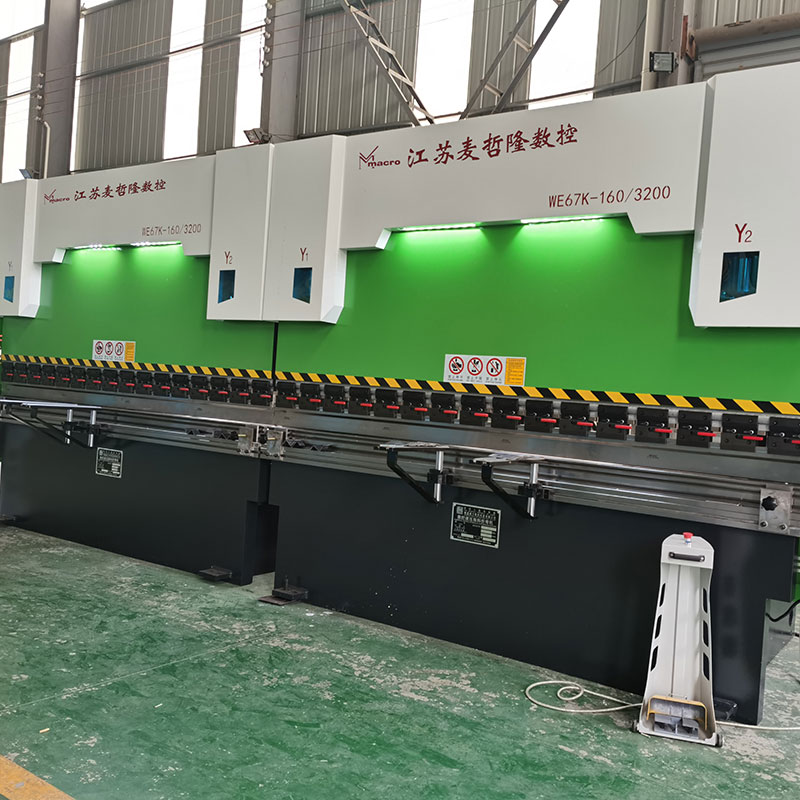

The double-machine linkage CNC hydraulic press brake machine is to connect two bending machines to perform bending processing. Two press brakes and two operating systems can work together or separately. The rear gauge and front feeding device are specially designed for large workpieces, which can reduce labor intensity and improve work efficiency. The whole machine frame adopts an all-steel welded structure ,has high strength and rigidity. It is equipped with the DA series imported from the Netherlands , ESA series ,and the CYB series from the Swiss CYBELEC company. The main oil cylinders on both sides are synchronously used German imported electro-hydraulic servo valves and imported grating rulers to form a closed loop. Control, the sliding block runs accurately, so as to ensure the bending accuracy and the repeated positioning accuracy of the sliding block. The compensation can be automatically adjusted by the numerical control system, which is convenient and accurate. The hydraulic system adopts the integrated control system imported from Germany to improve the working stability of the machine tool. The two-machine linkage CNC hydraulic press brake machine cooperates with different bending dies to manufacture various workpieces, which are widely used in aircraft, ships, automobiles, mechanical engineering, street light poles, power poles, wire lamp poles and other related industries.

Feature

1. Equipped with a deflection compensation mechanism, suitable for processing special workpieces such as street light poles and power poles

2. Equipped with the Dutch delem double-machine linkage synchronization device, the electro-hydraulic proportional valve works at the same time, and controls the two machine tools to work synchronously

3. The whole machine adopts all-steel welded structure,has high strength

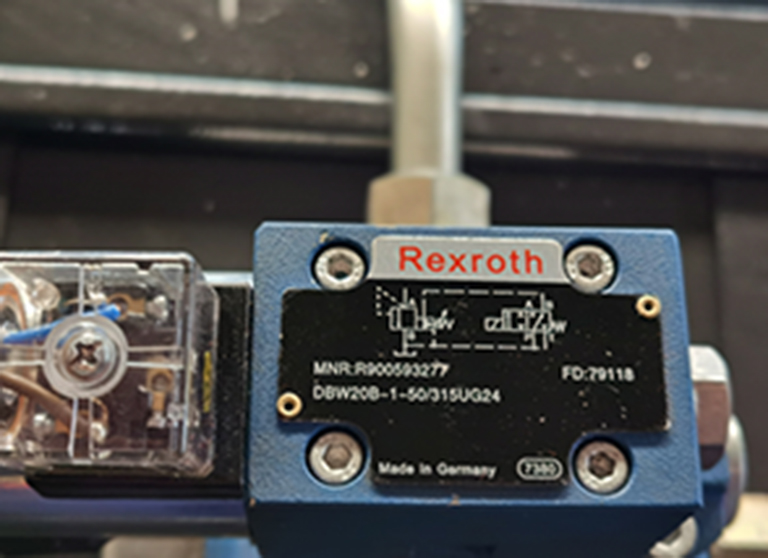

4. Equipped with imported electro-hydraulic servo motor, delem CNC system, grating ruler, Siemens motor, Rexroth valve, Schneider electrical components and other high-end configurations to improve processing accuracy

5. Repeatability precision +/-0.01mm,parallelism precision +/-0.02mm

6. Equipped with multi-axis and different molds, it can process high-precision workpieces at different angles and improve production efficiency

7. High bending precision,fast working speed, and efficient,operational safety,performance stably.

8. All machines satisfy ISO/CE high standard

Application

Hydraulic tandem press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic tandem bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, street light poles, power poles, wire lamp poles, new energy,stainless steel products and other industries.

Parameter

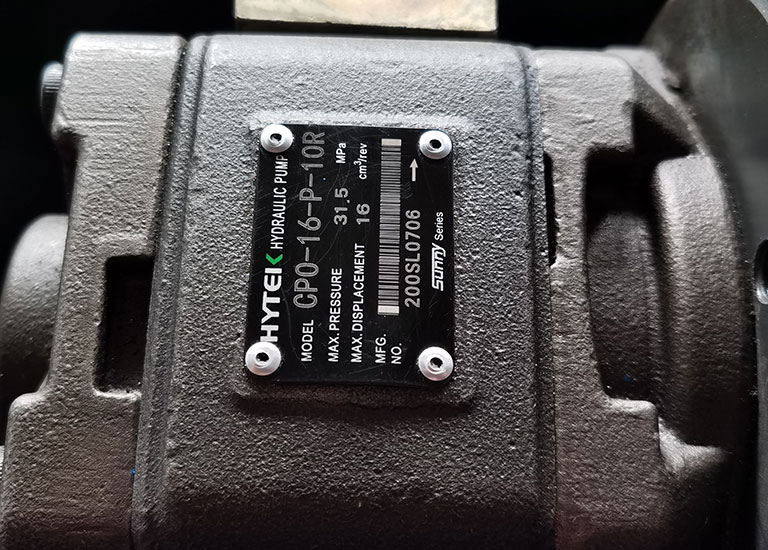

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):2X3200mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):1600KN |

| Motor Power(kw):2X11KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:320mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

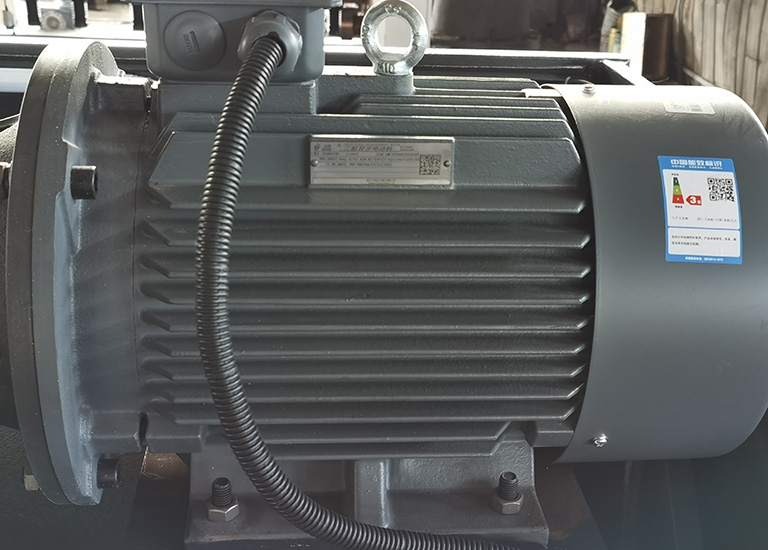

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

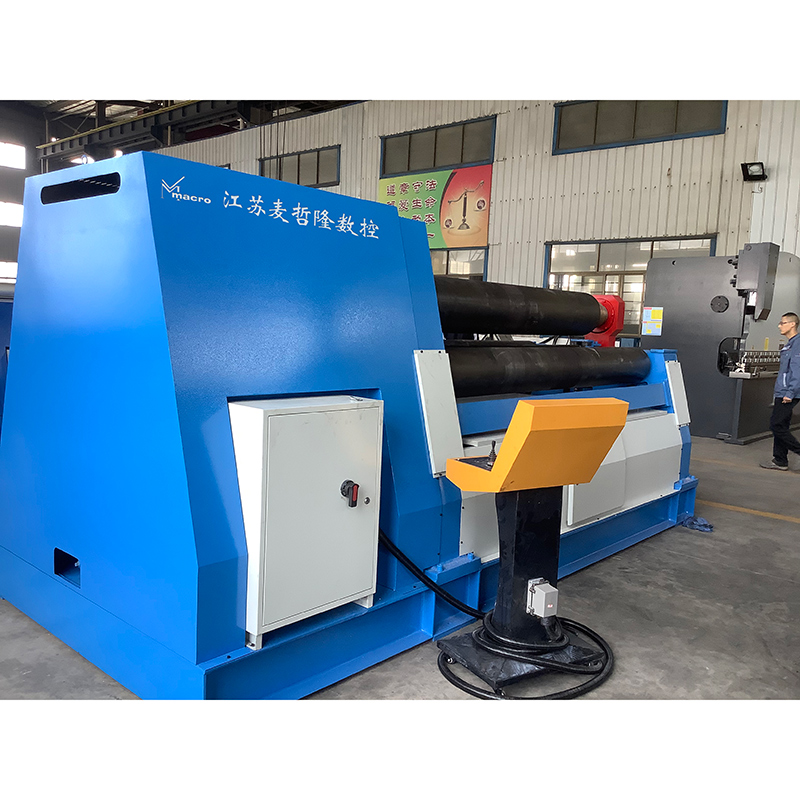

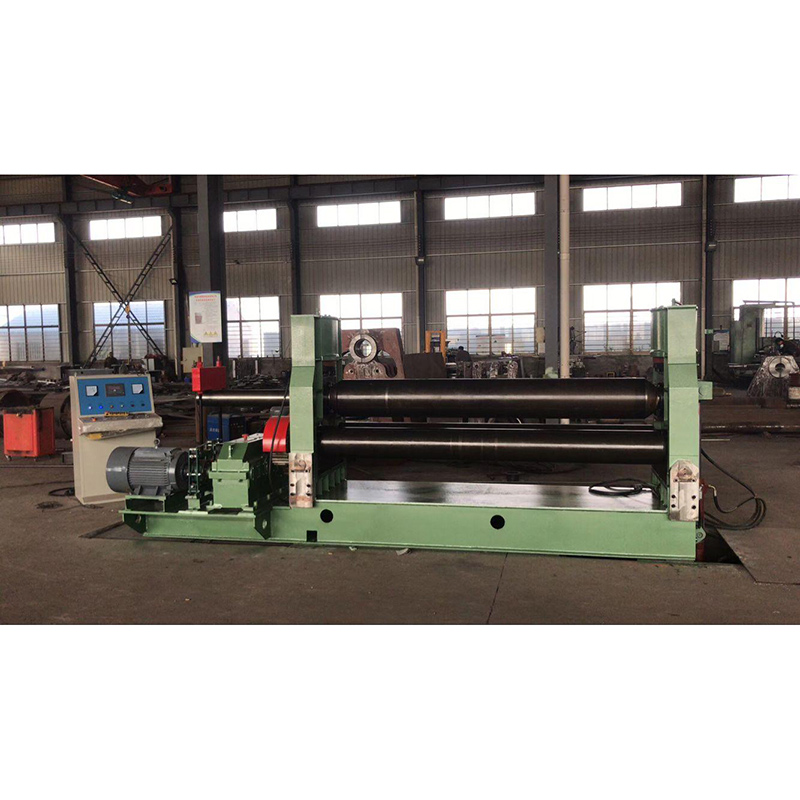

Samples

Machine Details

Delem DA53T controller

The DA53 CNC device has built-in control valve amplifier and PLC functions, which can be controlled not only by the torsion shaft synchronous bending machine, but also by the electro-hydraulic synchronous bending machine.

The panel mounting structure based on 4-axis control can be installed directly on the electric cabinet or in the suspension cabinet.With friendly user interface, TFT true color LCD display and menu drive, provide fast and concise programming tools.

Angle programming of the Y axis, table deflection compensation and pressure control are standard.

The da-53, based on the latest technology, provides a stable and reliable solution.It is equipped with USB interface, a great place to facilitate the product and mold quick backup.

Overall welding

Overall welding has high strength,have long life,high stability

Moulds

Optional moulds with high hardness,die have long service life

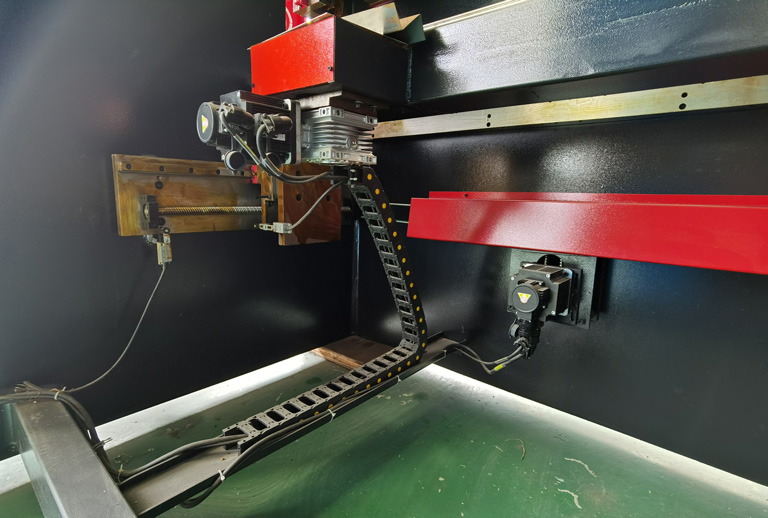

Ball screw and linear guide

Imported ball screw and linear guide can maintain high precision,reduce noise

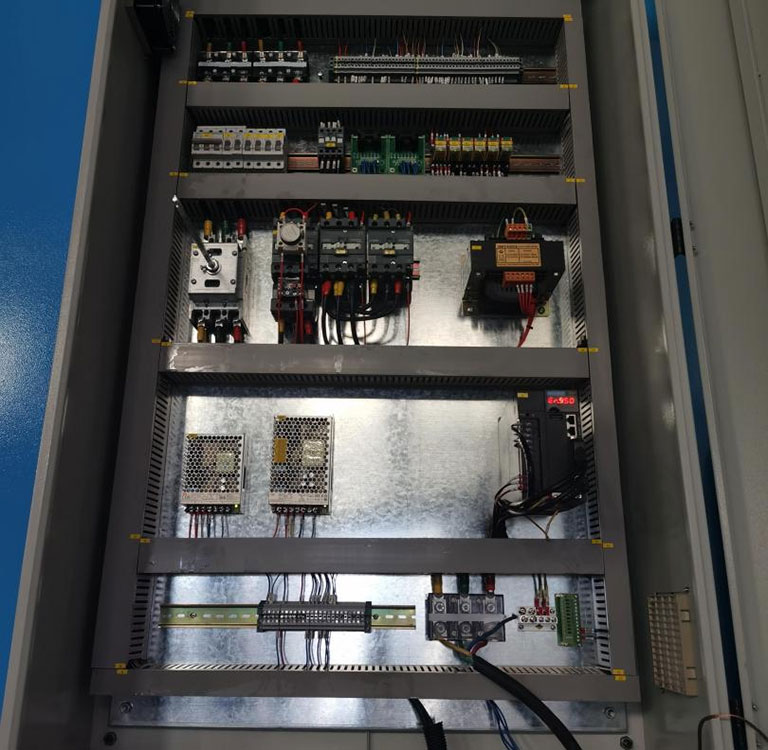

France Schneider electrics and DELTA inverter

Imported france schneider electrics components,ensure working stability

Siemens motor servo motor

Using Siemens motor servo motor guarantee the machine working stability

Sunny pump

Using Sunny pump guarantees machine in low noise working,provide power

Bosch Rexroth hydraulic valve

Germany bosch Rexroth integrated hydraulic valve block,hydraulic transmission with high reliability

Quick clampings

Using mechanical fast clampings reduce die-exchanging time,high efficiency

Front plate supportor

Simple structure,powerful function,supporting up/down adjustment, and can move along T-SHAPED channel in Horizontal direction

Optional Controller System

Product detail pictures:

Related Product Guide:

we can offer high quality products, competitive price and best customer service. Our destination is "You come here with difficulty and we give you a smile to take away" for Factory Price 48 Top 10 Press Brake Manufacturers - WE67K-2X160/3200mm CNC Delem DA53T controller tandem hydraulic press brake bending machine – Macro , The product will supply to all over the world, such as: Algeria, Yemen, Uzbekistan, Make sure you genuinely feel free to send us your requirements and we are going to respond for you asap. We now have got a skilled engineering group to serve for your just about every detailed needs. Cost-free samples could be sent to suit your needs personally to understand much more information. In an effort to meet your requires, be sure to seriously feel free to make contact with us. You may send us emails and contact us directly. Moreover, we welcome visits to our factory from around the globe for much better recognizing of our organization. nd objects. In our trade with merchants of numerous countries, we usually adhere for the principle of equality and mutual benefit. It is really our hope to market, by joint efforts, each trade and friendship to our mutual advantage. We look forward to getting your inquiries.

This enterprise in the industry is strong and competitive, advancing with the times and develop sustainable, we are very pleased to have a opportunity to cooperate!