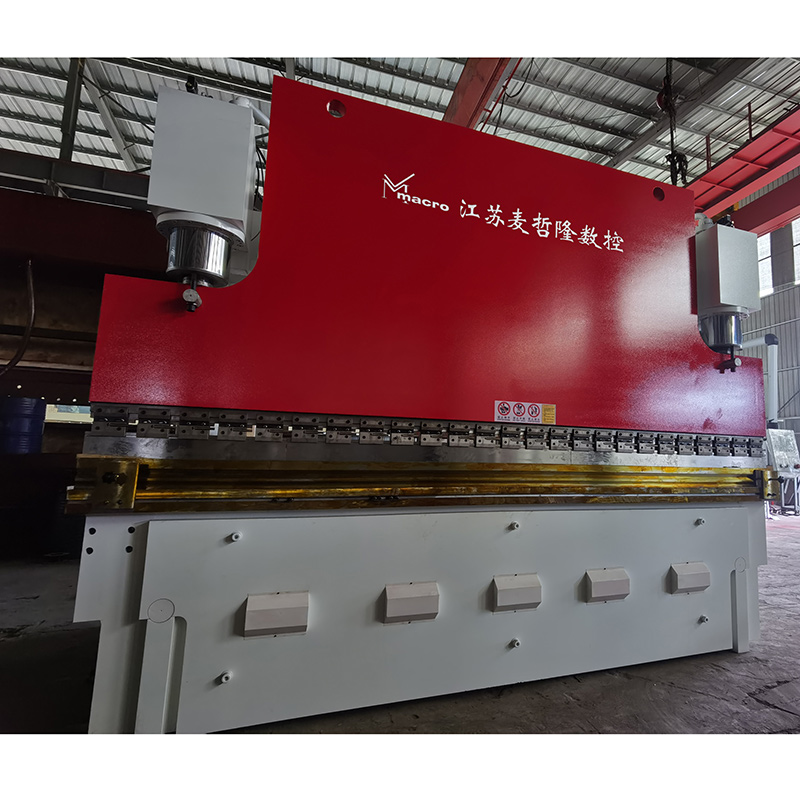

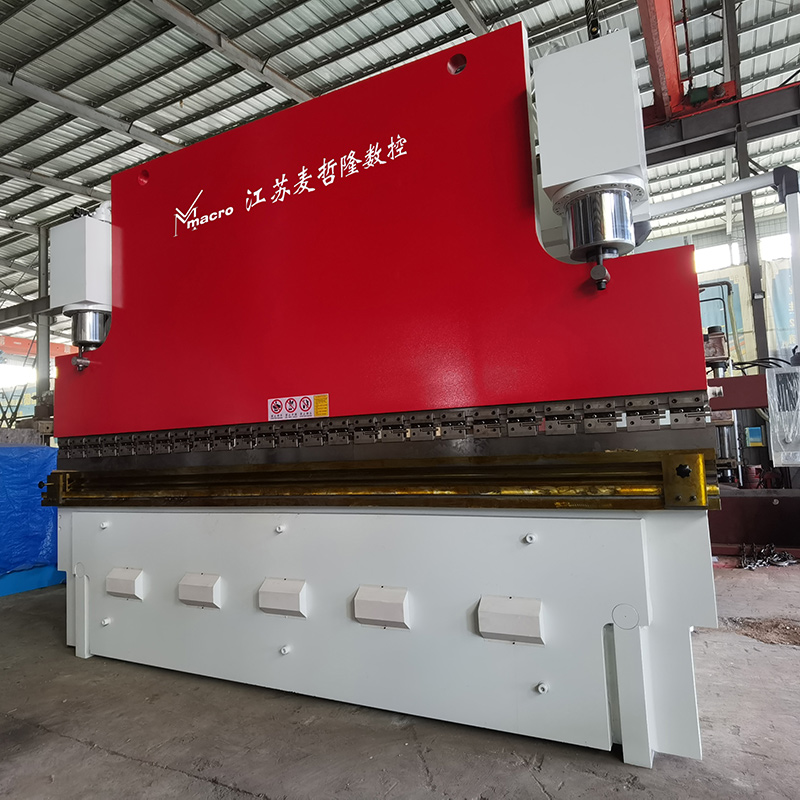

2022 High quality 115 Press Brake Tools - WE67K-2X500T/5000mm double-machine linkage bending machine tandem hydraulic press brake – Macro

2022 High quality 115 Press Brake Tools - WE67K-2X500T/5000mm double-machine linkage bending machine tandem hydraulic press brake – Macro Detail:

Product Introduction

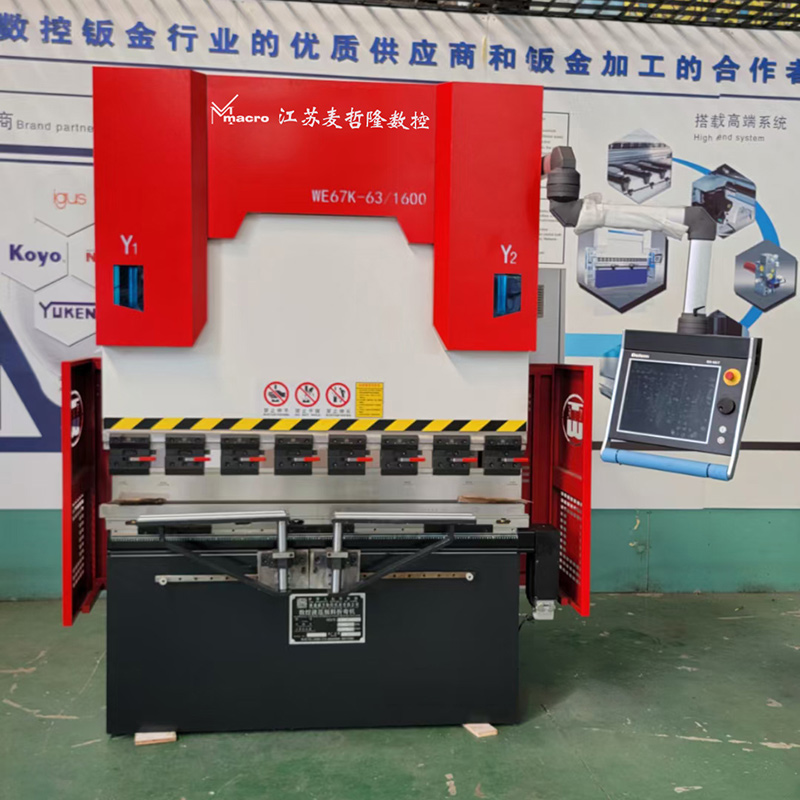

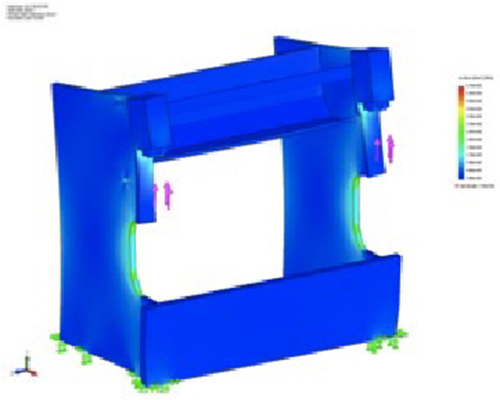

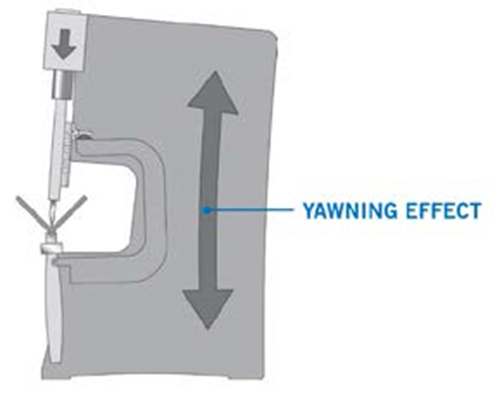

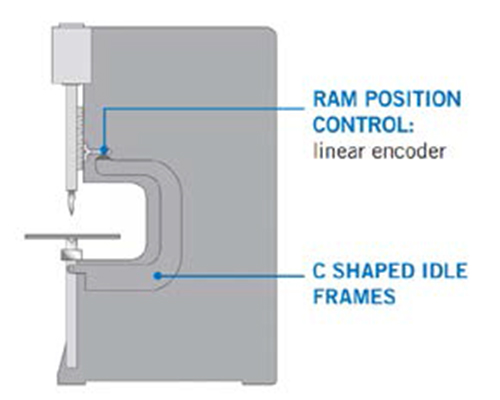

The electro-hydraulic servo double-machine linkage CNC bending machine is designed by ANSYS software which can ensure the reliability and precision of the press brake.Different high quality moulds are optional, according to customer’s requirements,such as Multi-V die,radius die,gooseneck die,etc.The worktable compensation device is adopted to ensure the bending accuracy of each workpiece.It is equipped with CYB touch 12 controller system, has high precision.It is equipped with imported famous brand servo motor,siemens motor,working stability, low noise.

Feature

1.With CYB touch 12 CNC controller system,6+1 axies.

2.High stability overall welding,long lifespan.

3.Precise positioning of back gauge.

4.With mechanical compensation or hydraulic compensation.

5.With specialize designed moulds to bend long workpiece.

6.Optional laser photoelectric protection or light curtain protection.

7.With safety guardrail to guarantee worker operating safety.

8.An experienced team of engineers debugs the double-machine linkage bending machine and trains your staff.

Application

Hydraulic tandem press bake bending machine can bend all thickness different angles of sheet metal stainless steel iron plate workpiece with high precision.Hydraulic tandem bending machine are widely used in Smart home, precision sheet metal, auto parts, communication cabinets, kitchen and bathroom sheet metal, electrical power, street light poles, power poles, wire lamp poles, new energy,stainless steel products and other industries.

Parameter

| Automatic level: Fully automatic | High pressure pump: Sunny |

| Machine Type: Synchronized | Length of working table(mm):2X5000mm |

| Place of origin: jiangsu,China | Brand name: Macro |

| Material / Metal Processed: Stainless steel,Alloy, Carbon Steel,Aluminum | Automatic: automatic |

| Certification: ISO and ce | Norminal pressure(KN):5000KN |

| Motor Power(kw):2X37KW | Key selling points: automatic |

| Warranty: 1 year | After-sale service provided:online support |

| After warranty service:video technical support,online support,field maintenance and repair service | Applicable industries:construction works,building meterial shops,machinery repair shops,manufacturing plants,furniture industry,stainless steel products industry |

| Local service location: china | Color: optional color, customer chose |

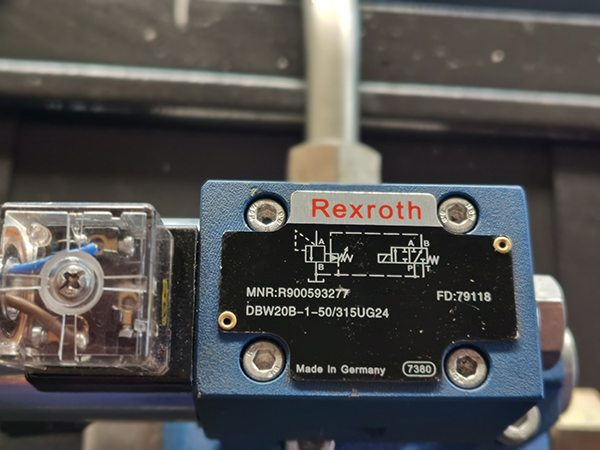

| Name: Electro-Hydraulic synchronous CNC Press Brake | Valve:Rexroth |

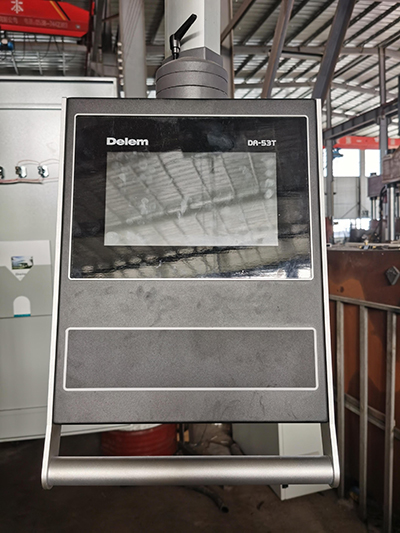

| Controller system: optional DA41,DA52S,DA53T,DA58T,DA66T,ESA S630,Cyb touch 8,Cyb touch 12,E21,E22 | Voltage:220V/380V/400V/600V |

| Throat depth:500mm | CNC or CN: CNC controller system |

| Raw meterial:Sheet/Plate Rolling | Electrical components: Schneider |

| Motor: Siemens from Germany | Usage/application: metal plate /stainless steel/iron plate bending |

Samples

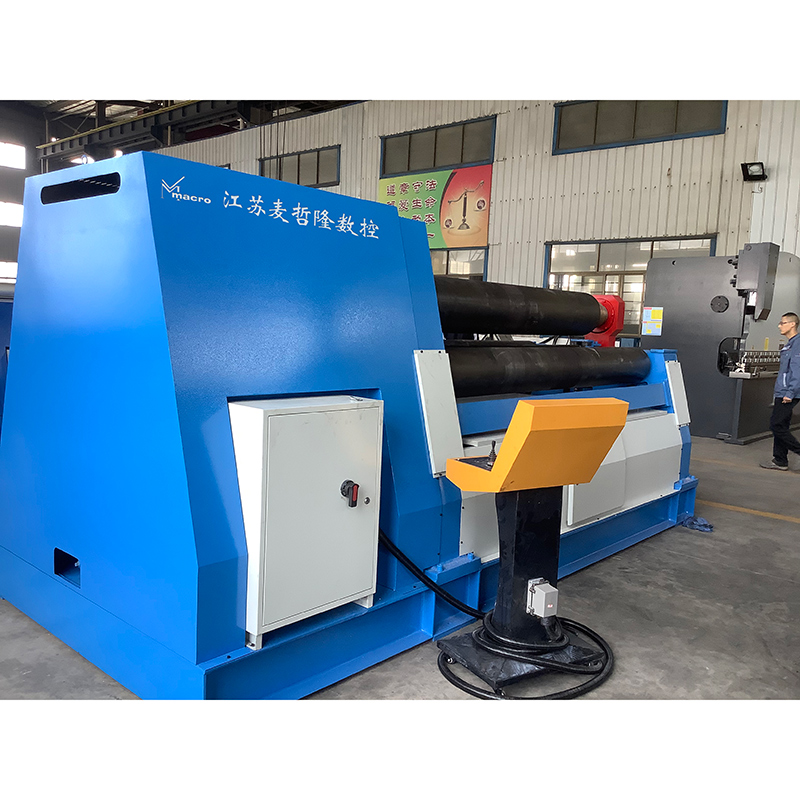

Machine Details

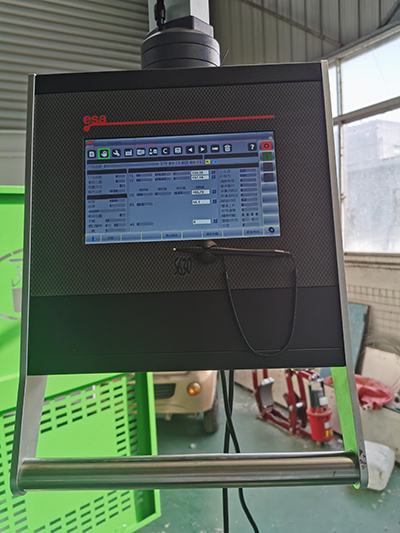

CYB touch12 controller

● Large screen, high definition and contrast touch screen system.

● Convenient interface, clear display and large icon buttons.

● Intuitive and friendly human-machine interface.

● Perfect programming can make batch multi-step bending more efficient.

● EasyBend page single-step bending is very convenient.

● Online help and pop-up tips make the software interface very user-friendly.

● Wireless software upgrades and data transfer are possible using a PC or laptop.

● Supports multiple languages.

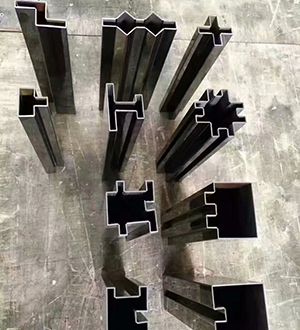

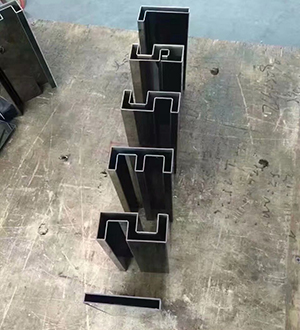

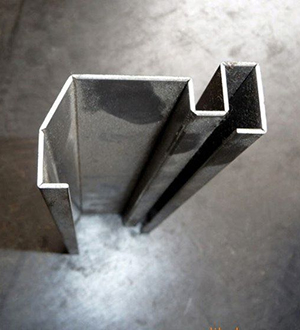

Moulds

Customized moulds accoring bending workpiece

Overall welding

Overall welding has high precision,long life

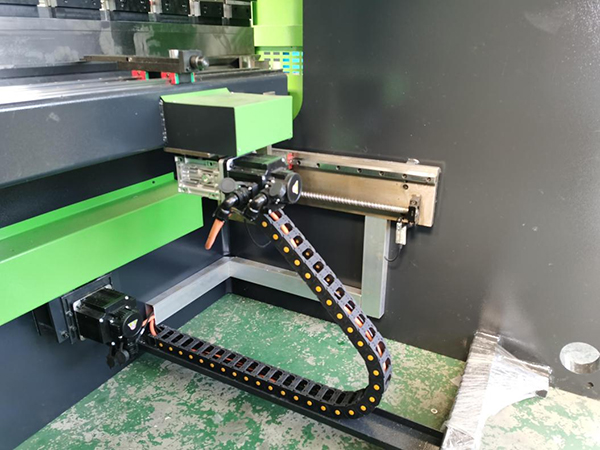

Ball screw and linear guide

To improve machine backguage accuracy

Siemens motor

Using Siemens motor with long lifespan

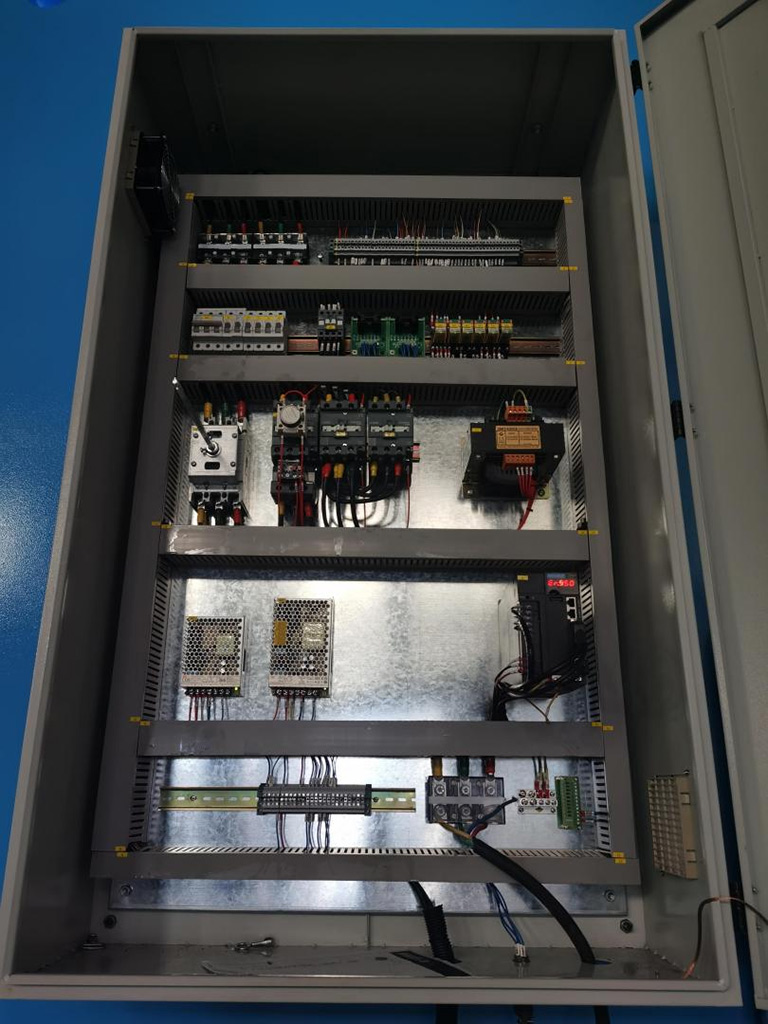

France Schneider electrics and DELTA inverter

high quality france schneider electrics,safey,Intelligent

Sunny pump

Using Sunny pump with low noise working, great power

Bosch Rexroth hydraulic valve

bosch Rexroth hydraulic valve are reliable,working stable

Front plate supportor

Used to support large sheet metal plates, to ensure bending quality

Quick clampings

Easy to change moulds,easy operate

Optional controller system

Product detail pictures:

Related Product Guide:

Normally customer-oriented, and it's our ultimate concentrate on for being not only one of the most dependable, trustable and honest supplier, but also the partner for our shoppers for 2022 High quality 115 Press Brake Tools - WE67K-2X500T/5000mm double-machine linkage bending machine tandem hydraulic press brake – Macro , The product will supply to all over the world, such as: Ghana, Bangalore, Swedish, because of our company has been persisting in the management idea of "Survival by Quality, Development by Service, Benefit by Reputation" . We fully realize the good credit standing, the high quality products, the reasonable price and the professional services are the reason that the customers choose us to be their long-term business partner.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!